Facade cleaning

Facades can be made of many different materials such as plaster, natural stone, glass, metal or wood. They lend a building an individual appearance. To maintain their visual appeal and value for as long as possible, regular building facade cleaning is necessary. Various techniques are available, particularly when using suitable equipment such as high-pressure cleaners, sand/wet blasters and dry ice blasters, which are used professionally depending on the material and type of dirt.

Cleaning facades: high-pressure is (almost) always required

High-pressure cleaners have proven to be an effective, economical method for facade cleaning and are used in most cases. Their low water consumption compared to working with a normal water hose and the high cleaning performance make them particularly appealing.

Selecting parameters: cleaning facades with a high-pressure cleaner correctly

Depending on the surface and type of dirt, water quantity, pressure, temperature and – if required – cleaning agent as well as exposure time can be adjusted. Large water volumes of up to 1,000 l/h loosen the dirt and remove it quickly through the cleaner’s flushing effect.

Together with the water volume, nozzle pressure and impact angle determine the impact pressure, i.e. the force exerted on the surface. High-performance nozzles intensify the mechanical effect and are around 40 percent more efficient than flat-jet nozzles.

If hot water is used to clean facades, temperatures between 60 and 80 °C help crusted deposits to break up faster. The depth of the clean is greater, so that root residues of moss and lichen can be removed, and regrowth can be prevented. If a cleaning agent is used as a support in facade cleaning, the surface type and the legal regulations must be considered.

Tip – Steam it up:

If stubborn dirt such as paint or bitumen coatings or sensitive surfaces are involved, the steam setting of a high-pressure cleaner can be helpful. The steam, which reaches up to 155°C, allows intensive facade cleaning and is gentle on the surface due to the low working pressure.

Looking for alternatives? Cleaning facades by sandblasting or dry ice blasting

Sand and dry ice blasting processes are important alternatives to high-pressure cleaning when facades can’t be exposed to too much water, or if water-saving processes are required. Additionally, if no cleaning agents may be used, or the amount of dirty water is limited by the circumstances, alternative solutions may be best.

How does it work? Sandblasting

In the low-pressure particle blasting process, known as sandblasting, a blasting gun is supplied with compressed air via a construction compressor. In addition, a very fine, soft abrasive and water are added to the air in the mixing chamber. It is important to select the properties of the blasting type to match both the dirt and the original facade surface type. The mixture of air, water and abrasive exits the nozzle of the gun, and the air pressure, water and abrasive quantities can be individually regulated. In this way, facades can be cleaned with minimal abrasion.

How does it work? Dry ice blasting

Dry ice blasting is a particle blasting process in which CO2 pellets of about 0.5 to 3 millimeters in size are used as blasting material. The dry ice pellets impact the surface at a temperature of -79 °C and a velocity of 150 m/s. In the process, they release their kinetic energy. The cold also makes the dirt brittle and fragile, so that it comes off more easily.

Another effect of facade cleaning with dry ice is that parts of the frozen carbon dioxide penetrate the cracks of dirt crusts or paint coatings, change from the solid to the gaseous state and literally break up the dirt through this increase in volume. All that remains are the radiated substances, which, depending on their quantity and composition, are either blown off with the compressed air available or picked up with suction cups.

Since the process is barely that abrasive and no abrasive residues, dirty water or moisture remain, sensitive facades can be cleansed of dirt gently and with minimal exertion.

Metal, wood, plaster, natural stone or glass: selecting a cleaning technology to match the type of facade

To clean facades professionally, the planned procedure should always be tested in advance on a test surface, regardless of the facade material. Questions to ask are: Is the facade sensitive to acid, does it absorb water? Which cleaning agent works best and in which concentration? If you do the prep, you will achieve the desired result and avoid loss or erosion of the substance or other permanent damage.

Cleaning metal facades

To reduce dirt on a facade, a high-pressure cleaner can be used. Cleansing brushes with soft natural hair or polyamide brushes (rigid or rotating) should be used. The reason is that water flows out through the large opening on the brush as a low-pressure jet. This avoids damage to the insulating layer behind the facade, and yet even strongly adhering dirt is usually removed quickly and in a water-saving manner.

To enhance facade cleaning, a suitable cleaning agent can be used. To extend the exposure time, the cleaning agent can be applied in sections in advance using a pump spray bottle.

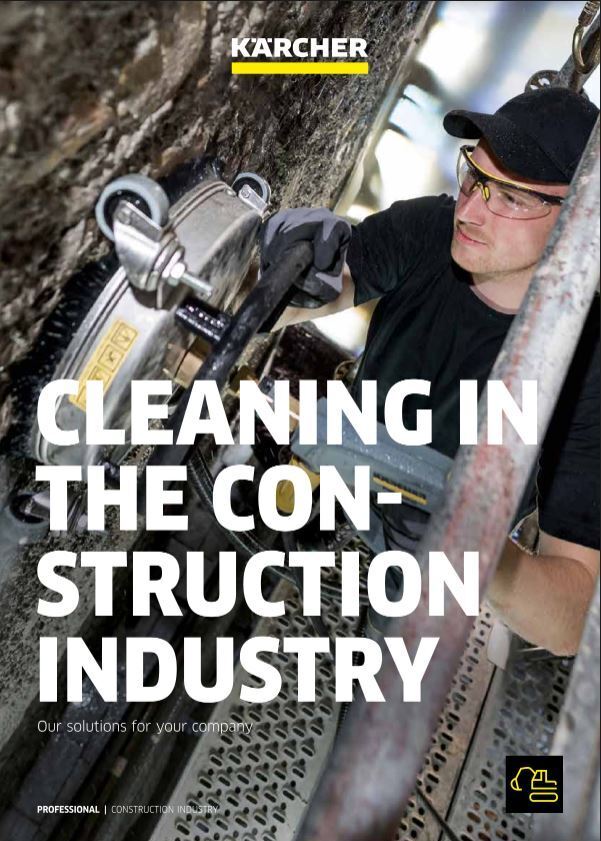

If dirt has become crusted and well-formed over the years, a cleaning agent with abrasive additives is used in combination with suitable facade pads made of white, scratch-free fleece to remove them. This work can be done manually or mechanically with the support of electrically operated handheld machines.

Finally, all cleaning residues are rinsed off again with clear water before the facade surface is stripped or leveled. Telescopic pole systems or a hoist can be used for this purpose. To maintain a uniform appearance for as long as possible, a preservative can be applied and carefully buffed out after the metal facade has been cleaned. In this way, the surface is also protected against emissions.

If there’s solid debris, such as plaster, mortar or concrete residues on metal facade s, this can be removed with wooden or plastic spatulas. This should be done as soon as possible, as the materials are strongly alkaline and can therefore cause irreparable damage, especially to anodized aluminum. Once the facade has been freed from any debris, initial cleaning can begin. The procedure for subsequent cleaning measures is analogous.

Cleaning wooden facades

Not all wooden facades are suitable for high-pressure cleaning. The facade should be made of untreated solid wood (hardwood or softwood) and be such that no water can reach underlying components (closed facade) or that the components behind the facade cannot be damaged by water. Whether the boards of the facade are laid vertically or horizontally, on the other hand, is irrelevant.

If wood is exposed to UV radiation, lignin, one of the main components of wood, starts breaking down. This leads to natural graying. To reverse this effect, hot water high-pressure works well. The facade cleaning is carried out without chemical agents and is therefore environmentally friendly. Thanks to the high temperature, work can be done gently and with little pressure, and dirt is dissolved much faster than with cold water. Dust, pollen, spores and mold on the surface can also be removed and in some cases even killed by the hot water. The result is an extensive restoration of the original appearance, depending on the degree of graying and the cleaning frequency.

For robust hardwood facades such as oak, hot water high-pressure cleaners with a pressure of around 100 bar and a temperature between 60 °C and 80 °C are advisable. More sensitive wood such as spruce can be treated with a pressure of about 50 bar. A flat jet nozzle should be used and an angle of 25° to 40° should be used. Rotating nozzles should not be used, as they can cause damage. If the application is too abrasive, this can be minimized by reducing the amount of water or increasing the diameter of the nozzle.

The distance between the nozzle and the surface should be about 20 centimeters, cleaning the wooden facade along the grain direction. It is also a good idea to wet the entire surface beforehand and then work from the top down, so that the lower part of the facade does not absorb the dirty water flowing down. As a final step, the entire facade should be rinsed again.

Cleaning plaster facade

Rendering exterior walls is a common architectural practice that offers versatile texture and colour options for building facades. To ensure that the shell of a building retains its aesthetic appeal, regular cleaning must be carried out in addition to repainting when needed. Our tips below will help you with plaster facade cleaning.

Stone facade cleaning

While the beauty of natural stone facades has been celebrated for centuries, the art of cleaning them can be somewhat tricky. Before cleaning facades or patios of natural stone, you must first identify the material you are dealing with as well as the overall condition of the facade or patio. It’s also important to assess the degree of soiling and the different types of soiling. Based on this analysis, you can determine which measures need to be taken and adapt cleaning methods accordingly. While one type of stone might benefit from pressure washing, low-pressure grit blasting may be more suitable for another.

Commercial window cleaning

Glass facades impart a transparent outer shell to buildings and play a major role in modern architecture. Different buildings have different types of glass, and it’s important to clean them both gently and efficiently. For post-build cleaning, scratch-sensitive glass surfaces such as tempered glass must be handled with particular care. For standard cleans, it is common practice to use purified water. This type of water removes dirt without the need for additional chemicals and unlike water from the tap, it dries without leaving behind limescale and other hard water stains.

Legal precautions: follow local regulations

Facade cleaning always takes place in a public space, so the legal regulations must be followed. Wastewater removal is subject to approval in many countries. If only dirty water is involved, the water can be discharged in many places after filtration and any collected solid debris must be disposed of. If a cleaning agent has been used, the water must usually be collected, filtered and neutralized. The relevant regulations must also be observed with regard to the use of blasting agents, the generation of dust, noise or waste gas.

Ergonomics: facade cleaning with a system

Cleaning large surfaces such as facades is physically demanding work. In addition to techniques that speed things up through good performance, accessories that support ergonomic work are important.

Multi-purpose telescopic lances, which are available in different lengths and materials make cleaning much easier. Details such as an anti-twist device, which prevents the rod from turning due to water force, or a rotatable base element, which allows effort-saving control of the telescopic system, further relieve the user. A backpack system that helps holding the rod via a spring balancer also provides additional ergonomic support and reduces some of the physical exertion.