Warehouse cleaning: how to make it easy

Maintaining a spotless material warehouse is undoubtedly beneficial.

This holds true for both very large warehouses and very small storage spaces, like those found in workshops.

Occupational health and safety as well as the preservation of warehouse inventory, however, are always crucial concerns. Specifically, to reduce the possibility of mishaps brought on by insufficient cleaning, the floors need to be spotless and secure to walk on.

Different cleaning machines for different types of dirt in warehouse

Dust will be raised by any movements made by warehouse personnel, forklift trucks, and floor vehicles when moving warehouse materials from point A to point B.

Vacuuming this dust systematically keeps the warehouse material safe and dust-free while also assisting in maintaining cleanliness and safety.

You can easily remove any dust, fluff and small paper residue with a broom, a (vacuum) sweeper or a vacuum cleaner – depending on the size of the warehouse.

Sweeping in the warehouse: Safely removing dust

A hoover sweeper is better than a single-purpose sweeper, especially when cleaning warehouses, due to the higher dust volumes involved. When sweeping, the hoover sweeper uses a roller brush to stir up the dust, a suction turbine (fan) to collect the dirt and a filter system to separate it. Cleaning the fine dust filters on a regular basis can significantly extend their service life.

Tip: Dust-free working

In order to work in as dust-free an environment as possible, there is a precisely fitting cover made of a PVC-coated linen fabric. It is stretched over the entire front area of the sweeper up to the rear wheels with a hook-and-loop fastener. The accessories therefore reduce dust dispersion even further.

Spot cleaning in the warehouse

For small, occasional cleaning tasks – whether on floors, on shelves or in storage rooms – a wet and dry vacuum cleaner of the appropriate size is the ideal solution since it is versatile and quickly ready for use, particularly in very small storage areas. This makes it quick and convenient to vacuum dust, water marks and spilled liquids. If you are cleaning very small storage shelves, manual equipment consisting of wiping cloths and buckets can also be used.

Floor cleaning in the warehouse with scrubber driers

The first thing that needs to be considered is the floor type. Small workshop warehouses often use ceramic tiles, such as fine stoneware tiles, because they are robust and have very low moisture absorption. Meanwhile, corporate warehouses and logistics centres often have industrial flooring made of screed or resilient synthetic coverings such as synthetic resin.

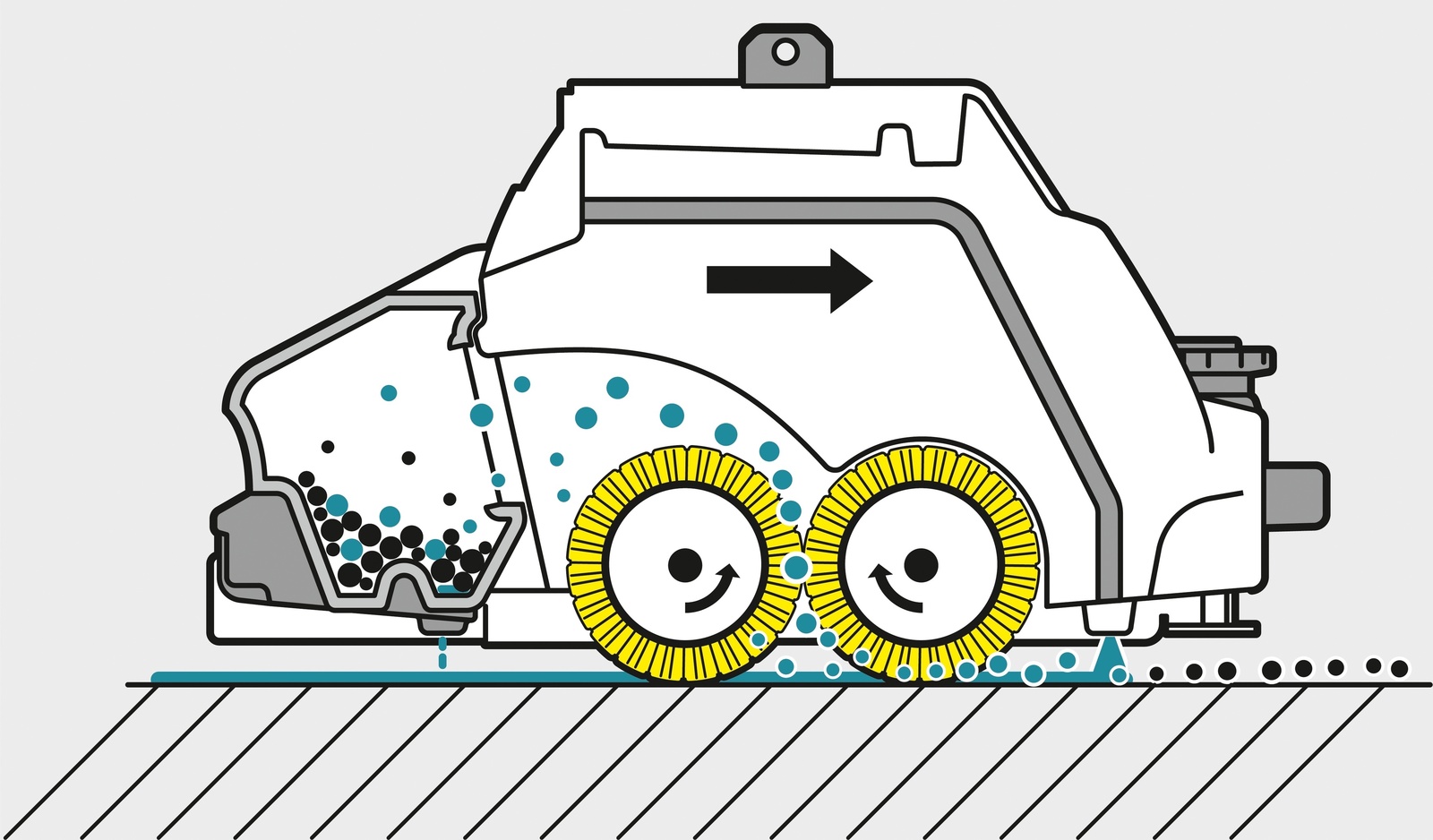

Since warehouse floors can vary so greatly, there is also a variety of cleaning technologies to choose from. Two of the main criteria for deciding which technology to use are the condition of the floor and the types of dirt in the warehouse. Scrubber driers with roller technology are particularly well suited to this type of cleaning because of the large amount of coarse dirt. This is because the remaining coarse dirt can be picked up in a single operation thanks to the rollers' pre-sweeping function.

Cleaning fine stoneware tiles

Fine stoneware tiles are an attractive, very popular floor covering which stands out thanks to its robust and slip-resistant qualities, as well as its very low moisture absorption rate. A modern and safe design medium, it is impossible to imagine floor coverings without fine stone nowadays.

Cleaning cement screed

Cement screed is the most commonly used type of screed. This floor covering requires special attention when it comes to cleaning and care. This is because it not only has to withstand a considerable amount of strain, but it also needs to meet occupational safety standards at the same time. For deep, maintenance and intermediate cleaning, it therefore all comes down to selecting the right equipment.

Mechanical process and cleaning tool

As a general rule, if it does not harm the floor, an alkaline cleaning agent should be used. If you use an acidic cleaning agent, you must ensure that cement joints are pre-soaked in water so as not to damage them.

In particular, when using scrubber driers in warehouses, you must ensure that these machines leave the floor dry. This is particularly important because the cleaned areas are often immediately walked on again or driven over by forklift trucks. It is imperative that occupational health and safety is ensured.

Combination machines for very large warehouses: Sweeping, scrubbing and vacuuming in one machine

We recommend using combination machines in very large warehouses with areas of over 10,000 square metres. In such areas, machines with dust suction and a filter area of up to 10 square metres are used. These machines sweep, scrub and vacuum in a single step, saving time and increasing productivity, especially when cleaning large areas. Moreover, the models with side brushes are particularly effective at removing loose dirt from walls.

The two types of combination machines:

1. Machines with a pre-assembled sweeping unit

What sets these machines apart is the fact that they come with a pre-assembled sweeping unit which cleans the floor dry before the downstream roller brush starts wet scrubbing.

These models work with a separate roller brush and provide excellent cleaning results. However, they have a long total length due to the addition of the pre-sweeping module (with a relatively large turning circle between shelf aisles) and dry cleaning can kick up larger amounts of dust. On the other hand, it is easy to empty the dry, collected dirt.

2. Machines with a large roller brush head for sweeping and scrubbing

Machines with an integrated sweeping function are referred to as having a large roller brush head. However, this equipment uses large brush diameters, some of which are 2.5 times the size of normal brush diameters, to sweep the dirt. The collected dirt is then usually discarded into a large container for high container emptying. These machines can continue sweeping automatically in scrubbing mode and also dry-sweep without water using a filter system.

The advantage of this is that all of the dust in the warehouse is trapped by the water. However, the waste container is more laborious to clean because it contains wet dirt. On the other hand, the machine is also much more compact and manoeuvrable and does not require an additional roller brush.

Removing tyre wear marks in warehouse

Particularly in larger (high-bay) warehouses, forklift trucks and floor vehicles travel several kilometres from one end of the hall to the other every day – generating not only dust but also leaving tyre wear marks on the floor.

Using a cleaning agent specially developed for efficiently removing tyre wear. The agent should be applied undiluted to the dirty areas and then left to work for a few minutes. The scrubber drier should then be used to remove the dirty water. Lastly, you should rinse everything down again with clean water.

Please note: Do not use this method on polymer-based or wax coatings, as the cleaning agent will remove them.

What's the ideal cleaning machine for your needs?

If you purchase a cleaning machine – whether a (vacuum) sweeper, a scrubber drier or a combination machine – you want the cleaning process to be comfortable, efficient and cost-effective. When deciding which machine to buy, you must consider the requirements of your warehouse, as well as criteria for the cleaning machine.

The following table provides an overview of factors and criteria that should be considered when making any purchase.

Size

Storage area criteria

- Calculate the size of the storage area

- As a rule, between 30% and 50% must be subtracted from the machine's theoretical area performance = practical area performance

- Discrepancies may arise, for example, due to not travelling in a straight line or interruptions

Machine criteria

- Theoretical area performance = metres travelled × working width when driving straight ahead per hour

(Vacuum) sweeper:

- For small storage areas: Manually operated and push models (up to approx. 5000 m2)

- For large warehouses: Ride-on machines

(from 5000 m2) - Very narrow areas: Dry vacuum cleaners

Scrubber drier:

- For small storage areas: Compact or walk-behind models

- For large warehouses: Ride-on scrubber driers

Type of flooring

Storage area criteria

- The type of dirt and floor covering in the warehouse determine the choice of roller brush/brush head

- Non-slip, robust

Machine criteria

(Vacuum) sweeper:

Choose from different roller brushes

- Standard (variety of surfaces)

- Hard (rough surfaces)

- Soft (smooth floors)

Scrubber drier:

Choose between roller technology and disc engineering

- Rollers: For coarse, textured flooring, with the required pre-sweeping function

- Discs: For smooth floors

Drive

Storage area criteria

- Warehouse material and condition of the building

- Battery-powered models are usually preferred in warehouses for fire safety reasons

Machine criteria

- Battery

- Liquid gas

- Combustion engine

Combustion engines are only suitable for well-ventilated areas

Manoeuvrability

Storage area criteria

- Check for narrow areas, dead ends, etc. and whether areas are clear of objects and furniture

Machine criteria

- Note the machine's turning circle

Costs

Storage area criteria

- Staffing costs compared to the time saved by machine cleaning

Machine criteria

- Acquisition costs

- Maintenance costs

Configuration

Storage area criteria

- Individual configuration according to the requirements of the working environment

Machine criteria

- Numerous accessories and extras are available

- Examples for scrubber driers: Side brushes, special tyres, protective roof, fast charger

- Examples for (vacuum) sweepers: Protective roof, working light, puncture-proof tyres