Truckwash RBS 6012

The ideal cleaning solution for a quick and gentle manual outer cleaning of commercial vehicles. The RBS 6000 is best suited for small fleets with buses, trucks, trucks with trailers or semitrailer trucks.

The RBS 6000 is a manually-operated single brush machine for commercial vehicles. It has been designed and developed based on Kärcher’s expertise in vehicle washing technology. The emphasis has been put on the gentle removal of traffic film by rotating washing rollers. The machine is the ideal solution for the quick and thorough all-round cleaning (sides, front and rear) of small fleets. In every washing process where water and detergents are used during the wash cycle, an aggressive environment is created. For this reason, Kärcher puts special emphasis on optimum protection against abrasion and rust of the plant components. Therefore the frame is an aluminium-welded construction. The compact construction on a rigid 6-guide-roller chassis guarantees high stability. The RBS 6000 is easily moveable with the help of 4 caster wheels (2 of them fixable). Two additional wheels ensure a excellent stableness and track reliability during the washing process. The forward movement along the vehicle is supported by the brush rotation. The plant combines - as a result of ideas of industrial designers - a clean appearance with high operating safety and optimal handling. The renowned German test-certificate "GS-Gütesiegel" proves this. The brushes (right and left movement) are controlled by deadman switches on both sides. Water supply can be stopped by a sliding cock. Detergent is mixed to water by means of a dosing pump. Plastic covered handles, a chassis frame with rounded edges and distance rollers protect the operator and the vehicle. The double-supported brush shaft is driven by a geared motor with a self-tightening chain drive. The white-yellow coloured brush (diameter in operation approximately 1,000mm) consists of profiled polyethylene bristles and those are gathered on individually exchangeable half shells.

Features and benefits

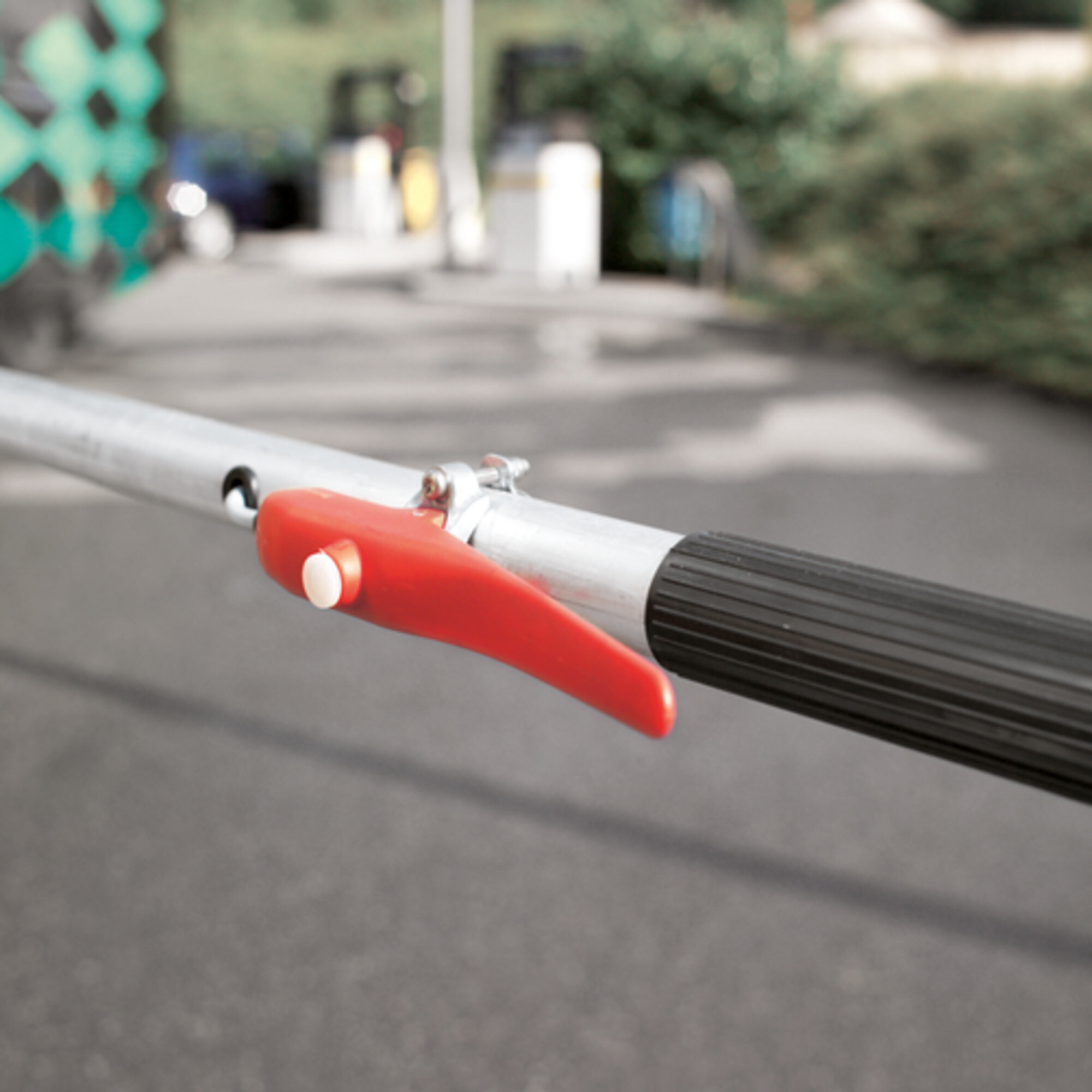

Adjusting wheel

Makes possible vertical contour detection and tilting mechanism. Vehicle fronts with angles of up to 10° are easily reached.

Detergent dosing

Cleaning agent can be added if required using a dosing pump.

Operation and safety handling

Brush rotation supports the operator during the forward movement of the system. Brush rotation stops when the handle is released.Light aluminium design

- Extremely hard-wearing against external influences.

- The half-shell cladding reliably protects the operator from splash water.

Four castors and 2 track wheels

- Excellent manoeuvrability and good stability.

- High directional stability during the vehicle wash.

Specifications

Technical data

| Washing height (Millimetre) | 3645 |

| Washing bay requirement (Millimetre) | 4620 x 1700 x 1500 |

| Number of phases (Phases) | 3 |

| Frequency (Hertz) | 50 |

| Voltage (Volt) | 400 |

| Weight without accessories (Kilogram) | 246 |

Scope of supply

- plant control cabinet

- wheels standard height

Equipment

- Number of brushes: 1 Unit

- PE-brushes, standard Kärcher design

Application areas

- For manually controlled allover external cleaning of commercial vehicles