Cleaning formwork thoroughly

The quality of the formwork is crucial when producing different concrete construction surfaces and elements such as precast concrete moulds. Special attention needs to be paid to the cleanliness of the formwork, as that’s what high-quality concrete surfaces demand. The formwork used to precast concrete should therefore be cleaned after each application. Powerful cleaning equipment such as high-pressure cleaners are very suitable for this purpose. The devices not only clean thoroughly but are also gentle to the concrete surface and flexible to use. They can also be used to remove hardened concrete residue without leaving any marks. The cleaner, water pressure and the quantity of water can all be adjusted depending on the amount of soiling. That way it’s possible to clean formwork thoroughly without damaging it.

Ensure high-quality concrete surfaces by cleaning the formwork

Concrete is a versatile and resistant building material that can fulfil multiple construction requirements for strength as well as for structure. For example, precast concrete elements are often used for the construction of walls, ceilings, and staircases. Particularly in the case of exposed concrete that is supposed to not only act as a surface but to also fulfil a design function, the quality of the formwork is important. Only clean precast concrete moulds produce a surface that is aesthetically pleasing.

Different parts of formwork

Formworks are hollow moulds that are filled with liquid concrete to give it its final shape. The formwork consists of the frame and a structure called falsework that keeps the formwork in place as the concrete dries. Depending on the desired look, the formwork can be made by using different materials. These can determine the final look of the concrete surface. Wood is a popular material, but metal or plastic are a better option for creating smooth walls. After the concrete has dried, the formwork can be removed and reused.

Cleaning precast concrete moulds regularly ensures quality and saves costs

The professional cleaning of precast concrete moulds is important to maintain its high quality. Even when the concrete has set, it’s difficult to remove the formwork without leaving some residue. Residues is noticeable when the formwork is reused on another concrete element. It’s especially important to stick to the special cleaning requirements of formwork in the case of creating multiple béton brut or raw concrete surfaces quickly. Only thoroughly cleaned formwork will ensure a consistently high-quality finish.

Usually, individual panels or boards are screwed together to create the precast concrete mould. Since these boards are never completely tight, there is always some concrete residue left. This residue can make the formwork uneven, which in turn will have an impact on the surface of the next concrete element. Therefore, cleaning of the precast concrete frame thoroughly is a must.

If the formwork is used for longer periods, it should always be cleaned immediately after its removal. Sometimes this might not be possible due to time pressure, for example. However, failing to clean the formwork can lead to increased costs as the final concrete may need to be reworked. The final cleaning could also take longer, or the formwork might have to be replaced completely.

Cleaning power tools

Working effectively on a construction site requires the right tools. The accumulating dirt and dust can take its toll on equipment such as shovels, wheelbarrows and other tools. To ensure the equipment functions reliably and safely in the long term, careful cleaning and maintenance must be an essential part of the work routine. Depending on the equipment and the amount of dirt, you can use different cleaning devices, from high-pressure cleanersto vacuum cleaners.

What to consider when cleaning formwork?

Concrete residue on formwork frames should be removed as soon as possible after the removal of the formwork. That way the formwork can be used multiple times. Cleaning the formwork is also the foundation for an even concrete surface. Various methods can be used to clean the precast concrete moulds, such as manual or mechanical brush cleaning, teeing off incrustations, or using ultra-high-pressure cleaners.

You should only use cleaning equipment that doesn’t damage the formwork. Sandblasters, angle grinders, wire brushes or similar tools are not suitable. If you’re using a spatula or scraper to remove the concrete residues, ensure they don’t leave any scratches. You can also replace the tedious work with an ultra-high-pressure cleaner.

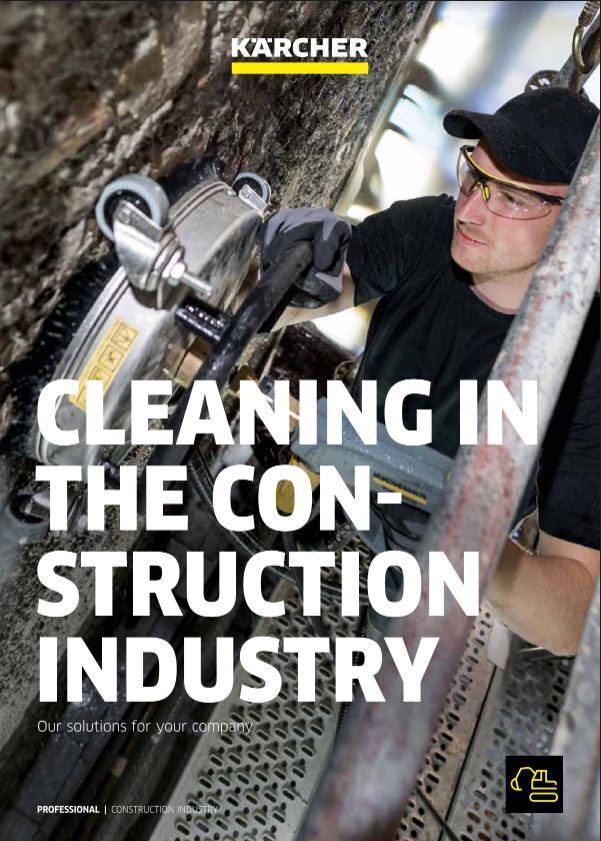

Cleaning scaffolding

Scaffolds are usually rented for the duration of a construction project and afterwards given to the next customer. As such, thorough cleaning is necessary to ensure they are safe and can be used for as long as possible, while maintaining their well-kept appearance. To achieve this, ultra-high-pressure cleaners are an excellent choice for removing any paint, concrete, or silicone residues that may remain on the surface of the scaffolds. However, it's crucial to select the appropriate accessories and water pressure to effectively cleaning scaffolding without causing any damage. By doing so, you can ensure customer satisfaction and maintain the safety and longevity of the scaffolds.

Effective but gentle cleaning of formworks with an ultra-high-pressure cleaner

How does a high-pressure cleaner work when cleaning precast concrete moulds?

High-pressure cleaners that work with a water pressure of up to 1,000 bar or more and have a high-water flow rate are called ultra-high-pressure cleaners. Thanks to their cleaning power, they can remove even hardened concrete residue from the formwork. In comparison, some low-pressure cleaners have a water pressure between 80 and 100 bar and the medium -pressure cleaners can produce a water pressure of around 150 to 200 bar.

The heart of every high-pressure cleaner is the high-pressure pump, it is usually driven by an electric motor or diesel engine. The pump is connected to a water supply and pressurises the incoming water. The water is fed via the high-pressure hose to the spray lance or another high-pressure tool with a corresponding high-pressure nozzle. Mobile units are usually built on a frame with a chassis.

Various water pressures, flexible application

Cleaning the formwork with an ultra-high-pressure cleaner is particularly effective. Thanks to the combination of water pressure, quantity, and the cleaning tool itself, the device’s power can be flexibly adjusted to the nature of the formwork material and the amount of dirt.

If the precast concrete is, for example, made of laminated plywood, you should use the cleaner at a reduced pressure of max. 500 bar to avoid damaging the wooden surface. On the other hand, ultra-high pressures (1,000 bar and more) can be used to clean the falsework, as it’s usually made of steel. However, to avoid damaging the surface of the formwork frame, steel abrasives should not be used with wet cleaning. It’s recommended to (pre-)clean the precast concrete frame on the construction site right after use, when the concrete residue is not completely hard.

Further aspects when professionally cleaning formwork

Thanks to the robust design of many ultra-high-pressure cleaners, they are easy to move around the building site. They are often attached to a sturdy steel frame with wheels and can easily be lifted with a crane. Reliable brakes ensure the device stays put even on uneven surfaces. The cleaner also has various mounts that carry different accessories to quickly switch between cleaning tasks.

The ultra-high-pressure cleaner also has other features that lighten the workload for both the worker and the machine. These include:

- The pre-pressure pump ensures an even supply of water, even when the flow is not constant (e.g., in a case a vehicle drives over the water hose).

- The water filter protects the pump from impurities, ideal in areas with poor water quality or when water tanks are used.

- The low-water cut-out automatically shuts down the unit if it’s not supplied with enough water, to protect the pump from damage.

- The pressure relief valve minimises the pressure in the hose when the trigger gun is closed, ensuring the safe use of the machine.

- The multi jet nozzle combines the high impact force of a point jet nozzle with the wide-spread performance of a flat jet nozzle for maximum effect.

After builders cleaning

Once construction work is completed, the next step is post construction cleaning – an ‘after builders cleaning’, so to speak. From dust on storage surfaces to paint splashes on windows to cement residue on tile floors, the cleaning tasks are as varied as the type of dirt itself. Thorough post construction cleaning involves the use of a wide range of equipment such as vacuums, high-pressure cleaners, scrubber-dryers, etc. to make the premises clean and safe.

Cleaning formwork properly: safety first when using ultra-high-pressure cleaners

As the water jet of ultra-high-pressure cleaners is very sharp, it carries an increased risk of accidents for users and bystanders. Wearing suitable personal protective equipment (PPE) is therefore necessary. When working with ultra-high-pressure cleaners one should be wearing a safety helmet, safety goggles, a face shield, hearing protection, a waterproof protective suit, a high-pressure apron as well as protective gloves and boots. It’s required by UK law to properly manufacture, store, use and maintain pressure equipment to ensure safety. The Water Jetting Association offers a very extensive code of practice for securely using high-pressure water equipment.

Tip – Determine a safe distance from the jet:

The closer you bring the ultra-high-pressure cleaner to the formwork, the smaller the processed area becomes. This in turn increases the time required for the task. In addition, the cleaned surface can be damaged if the distance is too short. On the other hand, the cleaning effect is reduced if the distance is too far. The tips below will help you to clean the formwork effectively:

- Approach the precast concrete first slowly from a greater distance with maximum power and keep the distance constant as soon as you reach a desired effect.

- If you can’t keep the distance as large as desired, blast at an angle.

- Blast from the left and right for uneven surfaces with a large roughness depth.

- For large surfaces, use high-pressure surface cleaning tools (such as Magnet Lizard, Vacujet or FloorMaster®) that can clean a wide area with a constant nozzle distance.