industrial cleaning solutions and systems

We can provide you with everything you need – and that is much more than we are able to present here. With our industrial vacuum cleaners, dry ice blasting ma chines, tank interior cleaning systems, high and ultra high-pressure cleaners, floor cleaners and sweepers, we cover virtually every requirement across all sectors of industry. Just tell us what challenge you are facing and we will tell you the most effective and efficient way of overcoming it.

Complete industrial solutions

Success on every level

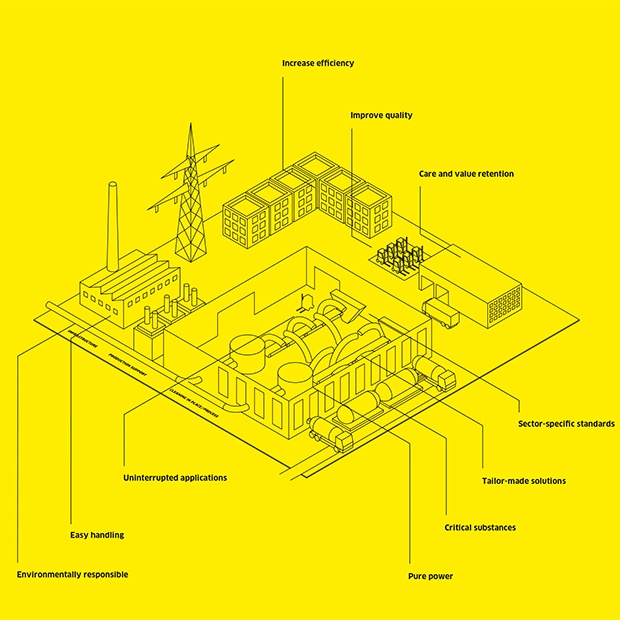

Since dirt knows no bounds, you need cleaning solutions that extend across all process levels of an industrial company: from infrastructure and production-related areas to production itself, the cleaning-in-place installation. For this variety of tasks, you need more than just the sum of individual applications. You need a system that guarantees the best results every time. And you get that from us.

Our Kärcher System

In collaboration with operators like you, we seek to de velop the most innovative solutions, products and services, always with the aim of creating an optimised system. A system made up of machines, accessories, cleaning agents and services which can be easily integrated into your operational processes and which brings real added value as an industrial solution. A system that makes a difference. Our Kärcher System.

One partner for everything

In industry, you are faced with a whole range of often very specific cleaning tasks: machinery and systems, moulds and parts, as well as transport routes and storage areas, both in doors and outdoors. Each one of these areas is very complex in itself. Combining all of them into one functioning system of the highest effectiveness and efficiency requires extensive expertise and experience. As world market leaders for cleaning technology, we offer this expertise and over 75 years’ experience. We offer the unique Kärcher System. And we offer the solution to every one of your tasks. What do you get out of it? All of the benfits.

Increase efficiency through intelligent cleaning management. By ensuring cleanliness in every area, you simultaneously improve quality. And with our innovative, gentle and protective cleaning procedures, you optimise care and maintenance of your systems.

By using our customised solutions for specific production environments, you can ensure compliance with sector-specific hygiene and safety standards at all times. For extreme or critical environments like Ex zones, danger zones, areas exposed to extreme temperatures and areas with limited accessibility, we offer highly specialised solutions. This enables you to promote your core business. And what’s more, you benefit from reduced downtime.

One of the most demanding cleaning tasks is the removal of critical substances. Whether explosive, hazardous, oily, greasy or stubborn dirt – with our special applications, virtually any type of dirt can be removed safely and reliably, without damaging your systems. And when it comes to tackling extremely in - tractable dirt and encrustations, all you need, where it is technically possible, is the pure power of water: our ultra high-pressure water jet systems remove any type of dirt, and even paint, coatings and cured concrete, in a targeted way.

Breaks are important, so long as they are planned. To ensure that this remains the case, we provide cleaning solutions which you can use parallel to your production processes without interruption. And with minimal set-up and changeover times.

Your working environment is already complex enough. That is why you will appreciate the easy handling of our cleaning machines. The same applies to our machines for special requirements. And to ensure that after successful completion of your cleaning you are not then faced with new problems, we support you with environmentally sustainable procedures for cleaning and processing production residues and waste water.

Industrial vacuums

Vacuum. Clean. Solid.

Vacuuming has countless applications in industry: from fine dust to coarse dirt, solids or liquids, mobile or stationary. We develop standard or customised vacuuming solutions for you for a wide range of sectors and areas of use. You tell us what you need to vacuum and where. We show you the best way of doing this.

Vacuuming even earns you money. In industry, cleanliness is an important requirement for consistently high product quality. And this is the basis for achieving higher prices on the market.

Advantages for you with our industrial vacuum cleaners

- Extremely robust – high-quality materials and durable connections

- Resilience that lasts for years

- Extra powerful machines, even for threeshift operation

- Safety vacuum cleaners for hazardous applications

- Customised special solutions for stationary operation

Application examples

- Metal shavings, granulate, punching waste

- Hazardous dusts

- Explosive dusts

- Coolants, lubricants and oils

- Powder

- Composite fabrics

Application areas

- Automotive industry

- Machinery and plant engineering

- Metallurgy and forming

- Tool making and metalworking

- Coking and mineral oil processing

- Glass and stone processing

- Paper production and printing industry

- Food industry

- Starch and tobacco production

- Rubber and plastic production

- Wood processing and furniture production

- Chemicals industry

- Pharmaceutical industry

- Local authorities

Metal processing industry

Automotive industry

Ultra high pressure cleaners

Combined competence. Outstanding power.

We have combined the competences of Kärcher and WOMA in order to develop the perfect ultra high-pressure cleaners for the toughest applications in industry and construction. The result is our new UHP (Ultra High Pressure) classes.

Our new UHP classes offer standardised, compact ultra high-pressure cleaners starting at 350 bar working pressure up to the Super class with an outstanding 2,800 bar working pressure. These performance levels are available as both mobile and s tationary process-integrated solutions. Custom-configured solutions can generate working pressures of up to 4,000 bar. The highly efficient industrial pumps used here come from our WOMA Competence Centre, the pioneer of ultra high-pressure technology.

The benefits for you

- Environmentally friendly

- Efficiency

- Innovative technologies

- Perfectly controlled power

- Safety for operators

Application examples

- Concrete restoration and removal

- Cleaning pipes, pipe bundles and heat exchangers

- Sieve, filter and tank interior cleaning

- Removal of coatings and paints

- Rust removal

- Surface preparation

- Abrasive cutting

- All types of surface removal

Application areas

- Automotive industry

- Shipbuilding and maintenance

- Food industry

- Chemical industry

- Machine construction

- Metal, steel and aluminium processing

- Stone processing

- Paper production

- Processing and refining of refined petroleum products/mineral oils

- Transport

- Construction

- Mining

- Building cleaning

- Public buildings

- Power plants

- Dismantling and decontamination

Heavy concrete removal with Aquacutter-robot

Multi-applications of round jet and turbo nozzle

Dry ice cleaning

Dry ice blasting: powerful, gentle, residuefree

Do you want a way to remove stubborn dirt that is as effective as it is gentle? Then the Ice Blaster from Kärcher is the right solution for you. The system uses compressed air and dry ice pellets to remove rubber residues, oils, greases, parting agents, dyes etc. from workpieces or surfaces.

Our Ice Blasters can be used even in areas where cleaning with water or sand is prohibited by law or is uneconomical. Dry ice pellets dissipate residue-free – without leaving any moisture. This means that you can also clean components for which conventional methods are not suitable, such as electric motors. You can very easily produce the pellets yourself using our pelletiser. And with the right accessories for all of the diverse applications, you always achieve outstanding cleaning results.

The benefits for you

- No more preparatory work

- Minimal machine downtime

- Environmentally-friendly cleaning

- Surfaces remain intact

- No residues

- Cleaning during production

- No dismantling required

Application examples

- Robots

- Moulds

- Filling systems

- Transport systems and conveyor systems

- Forklift trucks

- Hydraulic components

- Electrical components

- Control cabinets

Application areas

- Automotive industry, foundries and plastic injection moulding plants

- Printing plants

- Plastic and packaging industry

- Timber and paper industry

- Electrical industry

- Food, pharmaceutical and cosmetics industry

- Steel, metal and machine construction

- Local authorities and municipalities

Mould cleaning with the Ice Blaster

Removal of underbody coating with the Ice Blaster

Container cleaning

Tanks, silos, containers: cleaning to perfection

In transportation and industry, various types of containers are used for a wide range of substances. For professional container cleaning, we offer you customised solutions based on modular components.

We design your system for every cleaning purpose, the respective pro - duct and cleaning intervals. In doing so, we take into account specific factors like size and geometry, typical types of dirt and external factors. Our system solutions enable you to meet the diverse requirements of cleaning tanks, silos and containers professionally and in every respect.

The benefits for you

- Energy-saving

- Lower waste water costs

- Reduced installation

- High planning and cost security

- Maximum flexibility and mobility

- Modular design with tried-and-tested components

Application examples

- Tanks and silos

- 20 ft containers (ISO)

- Rail tank cars

- IB containers

- Barrels

- Containers of all kinds

Application areas

- Chemicals industry and trade

- Transport and logistics

- Food industry

- Breweries and drinks manufacturers

Tank interior cleaning solution (short version)

Tank interior cleaning solution

Reactor and boiler cleaning

System solutions for agitator vessels and reactors

You work with a variety of different substances and processes. It is clear that you need individual solutions to meet high hygiene and cleanliness requirements. And we provide these in every form: mobile, permanently installed, fully integrated and automated.

The simplified system diagram shows you how a modular cleaning solution could look for you. The mobile cleaning unit approaches the container and the movable spray head cleans all internal wall surfaces and components. Once cleaning is complete, the cleaning medium is fed back into the circulation tank and filtered. It sounds simple, but requires a high level of technical expertise and ex - perience. We have both. And we will dedicate our expertise and experience to finding the right solution for you.

The benefits for you

- Time saving and increased availability

- Process reliability thanks to reliable cleaning results

- Flexibility thanks to modularity

- Sustainability and efficiency

- Work safety

- From medium pressure (50 bar) to ultra high-pressure (1,500 bar)

- With cold or hot water or superheated steam

- With aqueous solutions, purified water,acids, alkalis or solvents

Application examples

- Agitator vessels

- IB containers

- Barrels

- Reactors

- Boilers

- Mobile containers

Application areas

- Chemicals industry

- Cosmetics industry

Stationary high-pressure cleaners

Permanently installed - immediately ready to use

Follow the example of the many industrial operators who have been using our stationary high-pressure units for decades on account of their high power, efciency and durability. One high-pressure unit can supply up to 17 points of use for simultaneous multiple lance operation.

Stationary high-pressure cleaning sys - tems can cover all of the performance ranges you need – efficiently, safely and economically. Guaranteed. High-pressure water is fed from a central supply unit via a pipeline system to fixed points of use, where it is kept ready for use in large quantities. Around the clock, 24/7 with no refilling, set-up times or working interruptions.

The benefits for you

- Reduced costs thanks to short set-up times

- Constant availability: everywhere, at all times

- Work safety

- Compliance with statutory hygiene standards

- Reduced efforts

Application examples

- Butcher’s shops and abattoirs

- General food production

- Decks on cruise ships

- Swimming pools and spas

- Industrial production systems

Application areas

- Food industry

- Cruise ships

- Automotive industry and garages

- Chemicals and metal processing industry

Parts cleaning

Perfect parts every time

Parts cleaners are absolutely essential in industrial production and maintenance. Are you still using solvents to clean dirty workpieces and tools? With our parts cleaners, you can achieve outstanding cleaning results entirely without solvents.

With our water-based parts cleaners and cleaning agents, you can remove grease, oil and any other kind of dirt thoroughly and effortlessly. Choose from automatic, manual and biological procedures.

The benefits for you

- Cleaning agents are water-based and environmentally sustainable

- Ergonomically arranged work area

- Robust and high-grade

- Reduced disposal costs

Application examples

- Tools

- Gearboxes

- Machine parts

- Engine components

- Oily and greasy single parts

- Components during maintenance

Application areas

- Garages and other workshops

- Service and maintenance companies

- Metal processing

- Cleaning of components in maintenance

- Manufacture

Parts cleaning in painting process

Automatic parts cleaner - setup

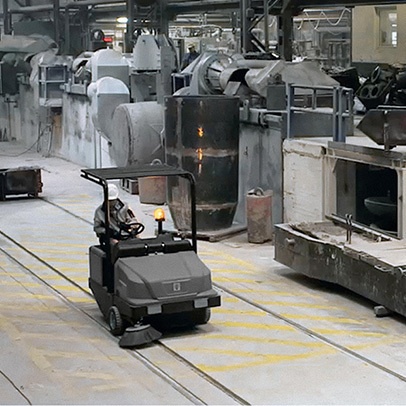

RIDE-ON SWEEPER

Handling harsh industrial environments

Kärcher sweepers offer large area performance, excellent cleaning results and numerous accessory options. They have different drive types for use in indoor areas, outdoor areas or both. Choose between one or two side brushes. Suction and advanced filter technologies for a dust-free environment. Larger ride-on sweepers have a hydraulic container lift for convenient high container emptying.

Economical and fast thanks to high sweeping efficiency. Large tank capacity and waste container with up to 600-litre capacity and hydraulic lift for continuous use. Rugged design for tough jobs in industry. Benefits of the Kärcher KM Ride-on sweepers are decisive.

The benefits for you

- Time saving and increased availability

- Can be used under tough working condition

- Good manoeuvrability and control even in tight spaces

Application examples

- Floor cleaning in production area & warehouse

- Removes fine dust and construction waste

Application areas

- Warehouse & construction site

- Metal industry