Cleaning commercial vehicles

Having clean commercial vehicles plays a key role in the positive look of a fleet. To save both labour costs and time, the demands on washing quality and speed are high. The size and design of the vehicles, however, not only require a special technology for the wash – the washing chemicals must also be right in order to clean trucks, buses, etc. cost-effectively.

Requirements for a commercial vehicle wash

The requirements for cleaning commercial vehicles are stringent. This is because the dirt that accumulates on trucks, etc. varies significantly depending on the purpose of use and vehicle type. The washing technology must therefore be able to reliably and quickly remove dirt such as tar spots, oils and mud stains along with seasonal deposits (e.g. road salt, flower pollen, insect and leaf residues) while being gentle on the vehicle surface.

Another challenge is the various materials from which the trucks are manufactured, ranging from aluminium, carbon fibre and steel through to rubber and various plastics. They must all be cleaned reliably and gently in a washing process.

Mechanical cleaning leads to time and cost savings

Mechanical cleaning helps save both labour costs and time. One efficient solution is therefore to use modern commercial vehicle gantry car washes and wash bays with high-pressure cleaners. These have a variety of features that enable the vehicle wash to be adapted to changing requirements. Their spectrum of use ranges from a manual or mechanical prewash to a thorough main wash right through to vehicle care. This makes it possible to use cleaning agents that have been specially formulated, without which it would be either impossible or extremely time-consuming to meet the stringent requirements for a commercial vehicle wash. The use of wash systems and bays must, however, be adapted to the type, number and size of the vehicles.

When selecting and equipping a wash system for commercial vehicles, three important questions have to be answered:

Which vehicles are to be cleaned?

When selecting and equipping a wash system for commercial vehicles, it is important to first clarify which vehicle types are to be cleaned. Construction vehicles with special structures are difficult to clean and usually require the use of a high-pressure cleaner as they cannot be driven through gantry washes. Alternatively, it is possible to install stationary spray arches without brushes for these vehicles. In contrast to a gantry wash, these arches do not move – instead the vehicles are driven through them and washed without making contact. This enables the vehicles to be washed without a great deal of manual labour. Articulated lorries, buses and trucks with box superstructures, on the other hand, can be cleaned far more efficiently with stationary gantry or mobile brush wash systems.

Vehicle wash for own purposes or as a contract business?

It is also important to consider whether the wash systems are to be used for a fleet company's own purposes or additionally or exclusively as a contract business. If they are to be used primarily for a fleet company's own purposes, the size and technical design of the systems depend on the number and type of vehicles. In the case of mixed fleets, a combined wash system may be required. This may also make it necessary to incorporate manual washing with high-pressure cleaners in addition to a gantry or mobile brush wash system for trucks.

The same applies to contract businesses. In this case, the wash systems chosen depend on the expected number of vehicles. This requires a thorough site analysis (e.g. number of visitors to site, number of companies based there with commercial vehicle fleets, regional competitive situations, groundwater protection laws).

Have construction and technical requirements been met?

Most wash systems available require a sufficiently large hall with water supply and drainage as well as a three-phase AC connection (400 V). Before installing the wash system, it is also important to check whether the size of the hall corresponds to the numerous safety regulations prescribed by trade associations (guidelines for vehicle wash systems ZH1/543). It is often also necessary to plan and purchase a separator for the wash water. If an indoor installation is not possible, some truck gantry car washes can be set up outdoors. In this case, a splash guard must be provided. The space required for the vehicle to approach as well as for preliminary and aftercare is also important. If the wash bay and hall are easily accessible during peak times and without repeated manoeuvres, this has a positive impact on customer satisfaction and therefore increases visitor frequency.

Three steps to a clean vehicle

Step 1: Prewash

A high-pressure cleaner is often used to prewash commercial vehicles. Before purchasing, it must be clarified whether a mobile or stationary machine is needed. A choice also has to be made between cold water and hot water high-pressure cleaners.

- Mobile machines are more cost-effective and the fact that they can be moved around means that they can be used for many (special) tasks such as workshop cleaning. However, note that these require longer set-up times. The capacity for consumables such as fuel and cleaning agent (approx. 10–20 l) is also restricted depending on the system.

- Stationary high-pressure cleaners have the advantage that the water can be heated by the power supply (electricity/gas/heating oil) without any limitations. Cords and supply lines are also kept tidy at all times and the tanks for the washing chemicals are also larger, meaning that they do not need to be refilled on a regular basis.

An alkaline truck and tarpaulin cleaner is used for the prewash. The pre-spraying agent for brush and high-pressure wash systems helps to soften and remove stubborn dirt such as grease, rust, oil, tar, insect debris and grey film. The dirt remover is either dispensed in the appropriate quantity using high-pressure cleaning machines or sprayed on thinly via the dosing system for the gantry car wash. An alkaline rim cleaner is used for the wheels if necessary.

Alternatively, it is possible to install an intensive pre-spray arch on the gantry car wash. Depending on the amount and type of dirt, this means that manual pre-cleaning may no longer be necessary.

Step 2: Main wash

During the main wash that follows the prewash, softened dirt is removed from the vehicle by three rotating brushes with the addition of water and a powerful shampoo or foam. Their active ingredient combinations help the brushes to glide and thus protect the vehicle surface. The contact pressure of the side brushes can be adapted to suit the particular vehicle which, in combination with the precise contour detection, ensures optimum washing results.

The main wash is followed by rinsing, whereby any remaining dirt and detergent residues are removed.

Alternatively, the main wash can also be carried out with a manually operated single-brush system. This cleans vehicles up to a height of 4.20 m and is suitable for fast, thorough all-round cleaning (sides, front and rear) of small fleets with up to 15 vehicles.

Step 3: Vehicle care

An additional programme, such as waxing, can then be selected to help maintain the truck. This protects the paint from any harmful environmental influences such as dust, acid rain or corrosive bird droppings. Wax also prevents corrosion since it flows into crevices and cavities penetrated by water and forms a protective film when it dries. Additional benefits are that dirt is less likely to stick to the paint, the vehicle looks its best for longer and is easier to clean.

Furthermore, liquid spray wax gives vehicles a brilliant shine and long-term protection. Since it is unaffected by water quality, it also provides a spotless finish after washing without blow drying. Liquid leather has been developed for vehicle wash systems without blow drying and is particularly suitable for vehicles with large visible surfaces. The product allows the wash water to flow away from the vehicle surface and windows as a thin film without leaving any marks.

Save money with the right chemicals

A large proportion of commercial vehicle wash systems use a water reclamation system in order to reduce fresh water consumption. This filters dirt particles out of the reclaim water, channels them away and returns the cleaned water back into the system – which can reduce fresh water consumption by up to 85 per cent. For efficient treatment of the reclaim water and safe operation of the wash system, however, the perfect match of washing chemicals is needed. This is because components such as the tank system with sludge trap, fine filtration system and reclaim water storage tank only work perfectly if they are not influenced by the chemicals. The manufacturer's specifications should always be observed.

System operators save money with the right chemicals. Additives that are selected according to individual requirements save water, which means the system runs safely and is paid off quicker. The customer also benefits from this, as a wash system with coordinated programmes and cleaning agents works to the highest level of quality with a low environmental impact – and thereby helps the vehicle retain its value and has a positive impact on customer satisfaction.

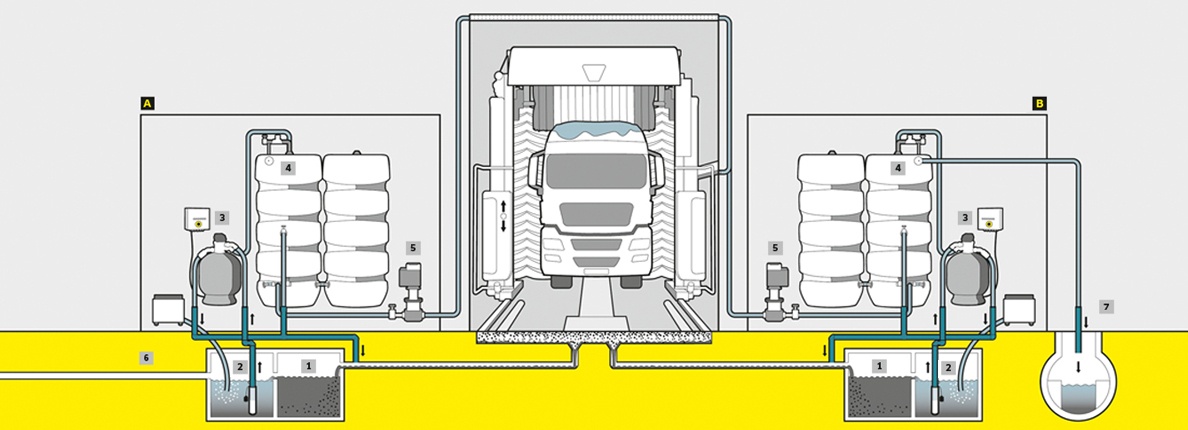

[A] Waste water discharge via tank system in sewage system | [B] Waste water discharge via reclaimed water tank in sewage system

Reclaimed water circuit: The waste water flows into a pump pit [2] via the settling pit [1]. From there, it is pumped into the reclaimed water tank [4] through the automatically back-flushable sand filter (media filter) [3] and made available for the wash process via a supply pump [5]. Depending on the applicable legal provisions, excess water can be channelled into the sewage system [6] either directly or through a separator by passing through the pump pit. The waste water can also be channelled into the sewage system directly from the reclaimed water tank [7]. In this case, there is no connection between the pump pit and the sewage system.