INDUSTRIAL CLEANING TESTIMONIALS

Clean processes, clean industry – specialist cleaning solutions for our customers.

Going beyond classic cleaning tasks, industrial cleaning is absolutely vital when it comes to optimising processes in production and logistics.

Experience in wide-ranging industries

Kärcher supports countless industrial customers across the most diverse range of sectors, with an annual turnover of more than EUR 300 million in this area. Bettina Biebl, Vice President Global Sales Management Professional, explains, "We often hear people ask 'Oh, does Kärcher do that too?' This is an incentive for us to increase awareness of our portfolio of consultation services and individual solutions for industrial cleaning." Looking at a few sample projects, it is clear that investing in cleaning technology soon pays off.

Value preservation up, production stoppages down

A textile company in Asia was faced with the problem that the cutting tool it was using had to be replaced every four months. The cost: EUR 100,000. By installing a vacuum system that removes the fine textile fibres from the blade, the useful life could be extended by one month. "We have had similar success with vacuum systems in the food industry," explains Biebl. "Ice cream tubs that are not filled by the production system, for example, often grind production to a halt." The reason: the jammed tubs have to be removed. A vacuum system, on the other hand, removes them automatically, allowing production to run smoothly.

Increasing employee safety

A solution that increases workplace safety was also developed for the drinks industry. The problem here was that loose labels would often find their way into the machines and bring them to a standstill. Removing them manually involves a high risk of injury to personnel. By implementing a vacuum system, separated labels are removed mechanically.

Clean faster, produce more

"Regardless of the industry, the result is always the same: whenever processes and technologies are analysed, there is always a need for improvement. And the return on investment soon materialises," asserts Biebl. Whether it's an industrial bakery that can produce goods for longer by virtue of reducing time spent on cleaning thanks to a belt cleaning solution, or a chemical company that has reduced the time involved in tank interior cleaning from almost four days to four hours, it pays to think outside the box – always.

IN CONVERSATION WITH CUSTOMERS.

Every area of responsibility within a company has different challenges to deal with. Alfred Weber (BMW Group Central Workshop Supervisor), Thomas Lauer (Manager of the Bitburger Group), Stefan Huber (Purchasing in the Hoffmann Group) and Dietmar Favorat (Global Advanced Technology Daimler Truck AG) report on how we solved these challenges together.

"I was surprised to hear that

Kärcher supplies dry ice blasters."

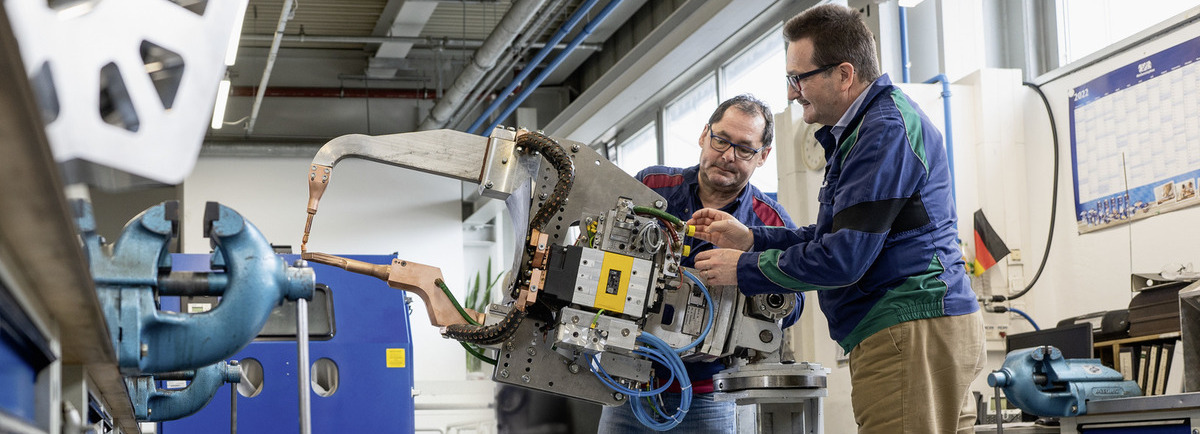

A conversation with Alfred Weber, BMW Group Central Workshop Supervisor in Munich, about the need to eliminate waste and always be ready.

You are the supervisor in the central workshop at the BMW plant in Munich. What falls under your area of responsibility and what are the greatest challenges you face in your work?

Challenges at work? We clean spot welding guns and grippers as well as adhesive equipment on robots. We also carry out machining work with turning and milling machines, as well as 3D printing. Before we can repair a tool, it needs to be cleaned. We can use mechanical aids for light soiling, but in many cases we use dry ice blasting. The greatest challenge for us is that we never know which tools are coming in for repair when or what condition they will be in. This means that 90% of our work cannot be planned – we're talking about 700 articles currently in circulation, depending on the tool category.

What is important to you when working with your suppliers?

I think how a business partner communicates with me is important. Are my needs being met, are there any suggestions for improvements, is there an honest answer to critical questions? We all know that there is no such thing as a one-size-fits-all solution and that every solution has its pros and cons. I want to be able to speak openly about this with my suppliers. Keeping appointments is also important to me – you can always cancel a meeting or call to say you're stuck in traffic. But to leave someone waiting without letting them know is unacceptable.

Together with Kärcher, you have optimised the cleaning of spot welding guns. What was the problem with your previous way of working and how has the new solution changed things for the better?

As we need to use dry ice to clean spot welding guns and other tools, we invested in a blasting cubicle and a dry ice blaster some time ago. To make sure we were always ready, however, dry ice had to be delivered every week. Sometimes we had no tools to clean, which meant that the dry ice evaporated. Or we had so many tools to clean that we didn't have enough. This was unsatisfactory from a cost and logistical point of view, but that's always the case with dry ice blasting. The dry ice blaster from Kärcher has eliminated this problem, as it produces the dry ice at the moment it is needed. This means we are always ready.

Do you use other Kärcher products and if so, why?

Yes. Actually, during a subsequent meeting, we touched on the subject of industrial vacuums. Our milling machines are cleaned once a week, which involves vacuuming up chips. The technician showed me the vacuum cleaners, which I knew by the name of Ringler – and they were exactly what we needed.

Which aspects of Kärcher as a company impress you the most?

I have been familiar with Kärcher since childhood thanks to its famous high-pressure cleaners. It is an established company with a very good reputation. I was truly surprised to discover that Kärcher also manufactures dry ice blasters and covers a far broader range of industries than I realised.

If you could ask for anything, which innovation(s) would you like to see next from Kärcher?

Honestly, an L2P dry ice blaster with more power (L2P = Liquid to Pellet). With more power, we would be able to use it for all cleaning tasks, including the cleaning of adhesive equipment, for example. If you ask me, that would be the key to selling L2P to industrial customers on a grand scale.

"As a brewery, we place great importance on cleanliness and hygiene"

A conversation with Thomas Lauer, Head of Technology/Production/Environment in the Bitburger Group, about cleaning technology and family companies

Bitburger is a family company, just like Kärcher. What do you think characterises family companies?

Family companies think in terms of generations and not in terms of quarterly reports, which means they have a different corporate culture. Sustainability is not a modern buzzword, for example, and the focus isn't only on climate and environmental protection.

The company is currently under the management of the seventh generation of the family. This means they have an entirely different connection to the company than shareholders in a public limited company.

What role does cleaning technology play in the drinks industry? Where are the greatest challenges?

Consumers are often unaware of how much time and work we as a brewery put into cleanliness and hygiene. At the weekend, for example, we clean the bottling plant in two shifts; the cleaning schedule is part of our production planning.

This makes cleaning technology hugely important to us, as it ultimately determines whether our product reaches the consumer in perfect condition.

What is particularly important to you when selecting cleaning technology solutions?

First and foremost, we need reliable, effective and environmentally friendly solutions. The cost-benefit effect plays a role too, of course, as we have to work economically. Let's take the example of the bottle cleaning machine for returnable bottles. We work with our cleaning technology suppliers to define treatment times, temperatures and other factors to ensure the cleaning process runs as effectively as possible and achieves the desired result. As far as the chemicals used are concerned, we work with manufacturers who develop products that are tailored to our specific requirements – we need, for example, lye with additives with a good cleaning power but minimal foam formation. As well as these special applications, we also have to think about the day-to-day cleaning of the production environment. We look for solutions that make our employees' work as hassle-free as possible.

You also use cleaning technology from Kärcher. Why did you choose those particular solutions?

We have been customers of Kärcher for a long time, as we appreciate the quality and having a service partner on site. The products are installed throughout our entire production facility, something I only really became aware of when I gave Kärcher employees a guided tour of the brewery. This meeting came about in quite a special way: at an event for family companies, the two families got talking and decided to bring together key employees from each company. I must confess that this initially felt like something of an imposition. But the meeting was fantastic and it was clear from the start that we were on the same wavelength. Since then, we have strengthened our cooperation even further.

Where exactly do you use solutions from Kärcher?

We have stations with Kärcher equipment on every bottling line, which we use for day-to-day cleaning. This includes high-pressure units, hose stations and further accessories. We use electrically heated high-pressure cleaners, for example, to remove logistics labels that supermarkets apply to our beer crates.

These are affixed so firmly that they have to be removed manually – the automatic process is simply not sufficient. We use industrial vacuums to remove the labels following the rinsing process.

If you could ask for anything, which innovation(s) would you like to see next from Kärcher?

An automatic Kärcher for my home that does all the cleaning for me. Joking aside, automatic systems are of particular interest for the brewery. I believe Kärcher is perfectly placed to develop these types of solutions. Automatic solutions would also be helpful for cleaning beneath and between the machines, in places that are difficult to reach. We would embrace anything that saves our employees time cleaning.

"Copycat products are not our thing"

A conversation with Stefan Huber, Purchasing in the Hoffmann Group, about the challenges in the field of industrial tooling & equipment

You are responsible within the Hoffmann Group for selecting products for the catalogue for industrial customers. What are the greatest challenges you face in your job?

I am responsible for the portfolio of power tools and workshop supplies. In terms of cleaning, we use vacuum cleaners and wet and dry vacuum cleaners from Kärcher, among other products. One of the greatest challenges is currently ensuring availability, as our customers expect a reliable supply. The portfolio of the Hoffmann Group is also based on our GARANT and HOLEX product brands as well as a targeted selection of manufacturers – so quality is extremely important.

What is particularly important to you when selecting cleaning technology products and solutions?

Cleaning technology rounds off our portfolio for industrial customers in the field of metal processing. This is what our customers expect, as it means we cater to all of their needs. When selecting cleaning technology products and solutions, we opt for established brands like Kärcher that our customers associate with user-orientated innovations. 'Copycat' products are not our thing – we value unique features that give our customers added value. Another important aspect is the international availability of products and services from a supplier, as we operate internationally.

How important is it for you as a company that suppliers focus not only on their products but also on efficient logistics and marketing?

We promise to deliver 99% of orders within 24 hours in Germany and Europe. In our Logistics City, which covers 100,000 square metres, we have 500,000 container storage locations and are able to send 40,000 packages per day within Europe. Our partners need to be able to keep pace with this, which means that accuracy and speed of supply are essential. Further aspects include having an electronic connection to our suppliers and a data interface to the PIM (Product Information Management) system so that the content, images and videos relating to products can be accessed directly.

You also have OEM products in your portfolio. What do you look for when selecting a manufacturer?

We generate more than 50% of our turnover with products from our GARANT and HOLEX brands. When it comes to OEM products, we choose premium manufacturers who can prove a high degree of vertical manufacturing and have a production capacity for large volumes. We are also interested in development partnerships, as our own brands are synonymous with innovation and uniqueness.

You have been working with Kärcher for some time. Which aspects of the company impress you the most?

We have enjoyed a very good partnership with Kärcher for a long time. I think there are many reasons why we are such a good fit: Kärcher is known throughout the world as a brand with a high performance promise, the quality and design of the product are just right, the company has a clear focus on industrial customers and the products create added value. It also has solid corporate values. Its roots as a family company are clearly apparent, proving it is a company you can rely on. When it comes to sustainability, something that is close to Kärcher's heart, exchanging information with such a strong partner enables us to develop our own end-to-end concept.

If you could ask for anything, which innovation(s) would you like to see next from Kärcher?

Actually, I would ask for two things. A wet/dry industrial robotic vacuum cleaner, and perhaps Kärcher could consider working with a larger battery platform. That could be useful in future when processing larger volumes.

"Rarely have I enjoyed experimenting as much as this."

A conversation with Dietmar Favorat, Global Advanced Technology Daimler Truck AG, about surface protection

and cleaning chemicals

You are an expert in surface technology and work for Daimler Trucks in the field of Global Advanced Technology. What are the greatest challenges you face in your specialist field?

My work involves developing effective solutions relating to surface technology with suitable technical partners. One such example is winter service vehicles. In order to prevent corrosion caused by the high load, we tested various preservative materials for underbody coating and corrosion protection. During this process, we established that relatively few customers had a vehicle cleaning concept in place. The background: when working with detergents that attack the preservative, we are not able to achieve the desired effect. As a next step, we tested various coatings and detergents. Kärcher and other manufacturers supported us in this task, which enabled us to develop a cleaning concept that is now recommended by our customer service. We deliberately assume no liability for this, as we have no influence over factors such as dosage, equipment or user errors.

Where do you come into contact with the topic of industrial cleaning and which solutions do you predominantly use for cleaning tasks?

Initially, I had no contact with it at all, but that changed when I became involved in the shipment of our trucks. HGVs are delivered around the world from our plant in Wörth am Rhein, some of them by shipment. As such, we also focus on things like protective wax for transport. After carrying out application tests at the Kärcher technical centre, we tested hot water high-pressure cleaners with steam jet and power nozzles at our plant and discovered that we could achieve the desired result much quicker with these and suitable detergents. We pass on the results of these tests so that our service partners can also benefit.

If you could ask for anything, which innovation(s) would you like to see next from Kärcher?

Over the coming years, electric transport is set to experience above average growth. For electric trucks, this will also involve new requirements for cleaning processes on components such as the battery, electric axis and electric motor. Different alloys and components made from diverse materials are machined for electric contacts, batteries and various other electric assemblies. That's why detergents should have the right pH value to ensure no damage is caused to the various substrates. We have been working with Kärcher since 2019 to develop a cleaning concept that contributes towards value preservation and enables damage-free cleaning of electric vehicles. This involves finding the maximum surface pressure that can be achieved but also the right detergent concentrate. As this is a topic for the future, I hope that Kärcher will soon be offering solutions.

Which aspects of Kärcher as a company impress you the most?

The company has an attractive range of products, in terms of both cleaning concentrates and equipment. What I find particularly impressive is the expertise in new developments and the expert technical and practical knowledge of the colleagues I have dealt with. Rarely have I enjoyed experimenting as much as this.

Dust-free logistics

After making large investments in logistics at the site in Biessenhofen, Head of Logistics Christian Bäckerbauer was adamant that the cleaning technology must keep pace. The key was in the details.

Problem

The site at Biessenhofen produces milk powder for infant formula and baby food, among other things. Dust accumulates on belts and the conveyor system, and this needs to be vacuumed up.

Solution

Kärcher vacuum cleaners with suction supply line and hoses as well as mobile models take the load off employees and ensure dust-free logistics.

Was it worth it? Facts and figures.

When processes are adapted, initial costs are involved. Only when input and output are proportionate and added value is being created does the investment pay off.

Challenge

- Mobile wet and dry vacuum cleaners were being used to clean the logistics area.

- An insufficient suction power resulted in a high dust impact in the warehouses.

- A huge amount of effort was required, as the vacuum cleaners had to be carried up and down stairs and from place to place.

Solution

- The use of industrial vacuums with sufficient suction power reduces the dust impact.

- Installation of pipelines to which vacuum cleaners can be connected for more flexibility.

- Connection points on various levels in packaging and logistics make handling much easier.

Short set-up times thanks to cleverly placed pipelines, long working cycles thanks to larger containers.

Reduced dust impact, a lower risk of accidents and less strain on employees thanks to ergonomic operation.

Maintenance effort reduced by 30 per cent thanks to less frequent filter replacements and a longer service life.

The industrial vacuums have a 25 times longer lifetime than the vacuum cleaners that were previously being used.

Preventing waste

In the central workshop at the BMW Group plant in Munich, the L2P dry ice blaster has improved logistics and processes – much to the satisfaction of workshop supervisor Alfred Weber.

Problem

Dry ice was previously being bought in to clean tools by means of dry ice blasting. Due to the fluctuating workload, either dry ice was left over or there was none available when it was needed.

Solution

The L2P dry ice blaster produces dry ice on demand, meaning that work can be carried out at any time and waste can be prevented.

Was it worth it? Facts and figures.

Sometimes it's obvious that an existing process is inefficient – but you can't seem to find alternative solution. But sometimes, with a bit of luck, the right product presents itself when you least expect it.

Challenge

In order to guarantee smooth production, spot welding guns and other tools need to be cleaned and maintained.

- The frequency and timing of work cannot be planned.

- For dry ice blasting, the dry ice has to be purchased in advance, which means that large quantities often evaporate having not been used.

Solution

The fact that there was an existing infrastructure for dry ice blasting meant that the new L2P dry ice blaster could be purchased and used straight away.

- The machine produces the dry ice from CO2, which can be stored in bottles.

- This makes cleaning possible at any time, prevents waste and completely eliminates the need for logistical planning for the purchase of dry ice.

Value preservation for long-term use of the tools. Downtimes in production are minimised thanks to prompt cleaning and maintenance of the tools.

Increased productivity in the maintenance department, as cleaning can be carried out at any time.

The investment in an L2P machine pays for itself extremely quickly, as no dry ice is wasted. The ROI is less than two years!

Cost savings of €6600 per year, as only as much CO2 as is needed has to be bought.

Tracking down system faults

Processes often involve problems that no-one attends to. Data light barriers in storage systems often cause failures, for example, even though the solution could be quite simple.

Problem

Automatic storage systems use countless wooden pallets. These bring a huge amount of dirt into warehouses, contaminating data light barriers in the process and causing system faults.

Solution

Installing a pallet underbody vacuum system before the pallets enter the warehouse solves three problems and ensures everything runs smoothly.

Was it worth it? Facts and figures.

Overlooked details can often cause problems that are initially a mystery. Once the solution is found, a huge amount of time and money can be saved.

Challenge

Wood chips or dirt deposits on pallets can interfere with data light barriers.

- This causes malfunctions and results in systems having to be shut down.

- The system can be restarted after manual cleaning has been carried out.

Solution

Installation of an automatic pallet vacuum system before the pallets enter the warehouse.

- Fault-free operation of the system without interruptions.

- No more manual cleaning by logistics personnel.

Downtime minimised by 50 hours per year – Smooth operation is guaranteed, as the light barriers no longer signal a fault.

Increased employee safety – The pallets no longer bring dirt into the warehouse, thereby reducing the risk of slipping.

25% less cleaning time – Intensive cleaning of warehouse floors and the manual cleaning of the light barriers are no longer necessary.

€30,000 saved per year – The minimisation of downtimes and cleaning times results in a fast return on investment.

REACHING THE GOAL.

Finding out where the problem lies. Finding the one detail that is having a huge impact. Developing solutions that are outside the box – this is what we do when it comes to cleaning technology for industrial customers. And it is only be working together that we can reach our goal.