Cleaning fine stoneware tiles

Fine stoneware tiles are an attractive, very popular floor covering which stands out thanks to its robust and slip-resistant qualities, as well as its very low moisture absorption capacity. A modern and safe design medium, it is impossible to imagine floor coverings without fine stone nowadays.

A robust and slip-resistant floor covering

Fine stoneware tiles are an attractive, very popular floor covering which stands out thanks to its robust and slip-resistant qualities, as well as its very low moisture absorption rate. This type of floor covering is available in many variants and colours, which has allowed it to be successfully used in different types of buildings – including workshops, commercial kitchens, service stations, hallways, hotel lobbies and on railway platforms. A modern and safe design medium, it is impossible to imagine floor coverings without fine stone nowadays.

The fine stoneware tile is composed of a treated, homogeneous clay material. The spray-dried mass is pressed under high pressure, fired at a temperature of over 1200 °C and is heavily sintered out in the process. This produces a particularly hard floor covering with very firm qualities and a very low water absorption capacity (less than 0.5% by weight), meaning that it can also be used in outside areas – water is not able to accumulate in the tile and so chipping is only very rare, even in frost. There are different types of fine stoneware tiles: Surface-treated tiles (brushed, rough-polished and polished) and untreated tiles with a textured or natural surface.

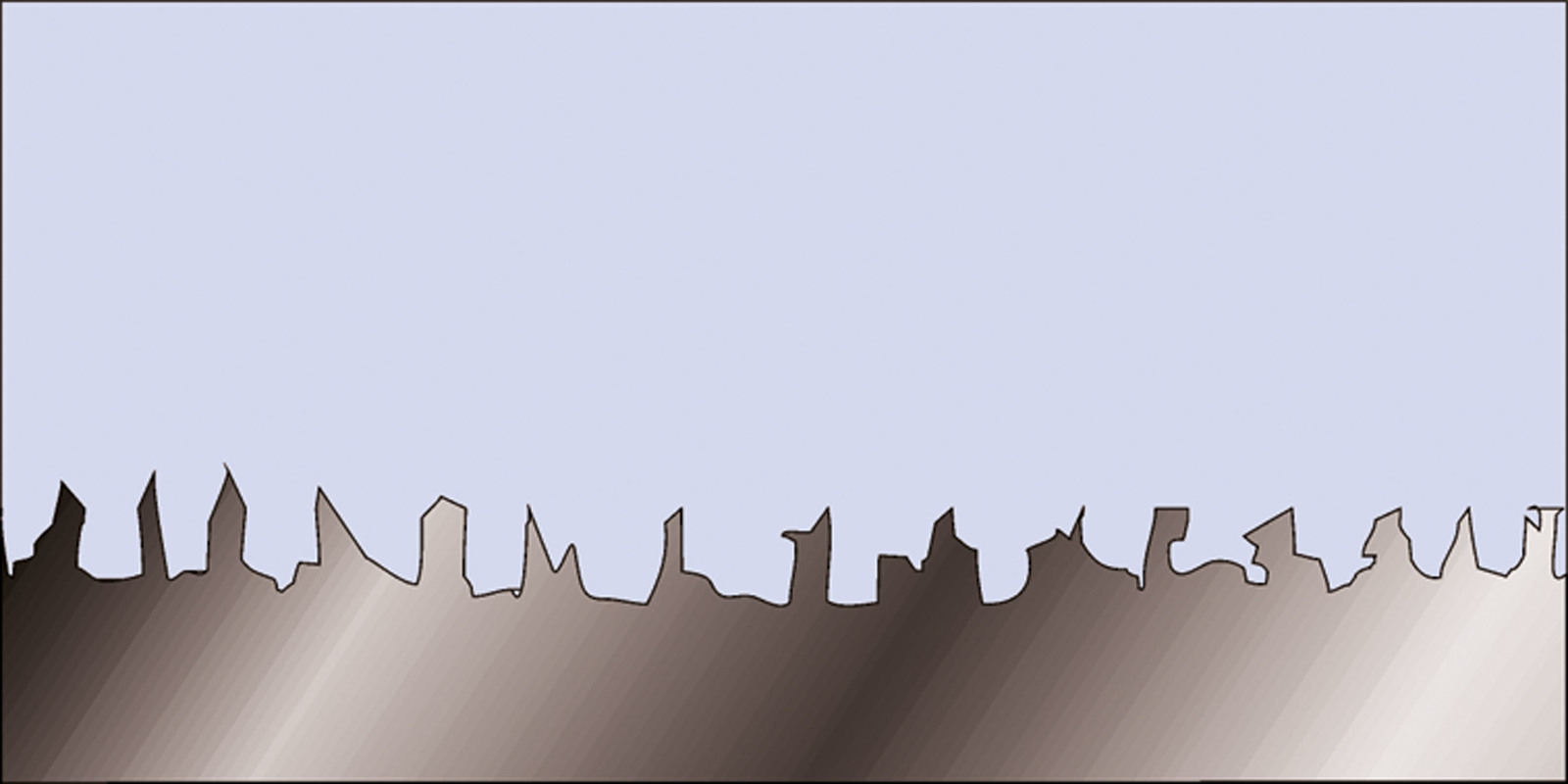

As all of these fine stoneware tiles have a microporous surface, they can also be penetrated by very small dirt particles. This penetration can be exacerbated by using cleaning agents containing surfactants. Surfactants reduce the surface tension of the water, making it easier for contaminants and dirt particles released in the water to penetrate into the fine pores. Resoiling is also encouraged by surfactant residues on the surface.

This results in greying, which presents a major challenge for floor cleaning. The requirements for cleanliness, value preservation and anti-slip protection can only be met by using suitable cleaning agents and microfibre cleaning textiles which remove the dirt from the surface texture.

Cleaning with scrubber driers

The use of scrubber driers is recommended for workshop floor cleaning. The cleaning agent is dosed into the water from the fresh water tank, or the water and cleaning agent are mixed beforehand. The mixture, known as the cleaning water, is transported to the scrubbing head and fed to the floor via the brush system. When combined with the pressure from the brushes, this removes the dirt. The trailing squeegee absorbs the dirty water again and feeds it into the waste water tank.

The right model: Advantages of the roller scrubber machine

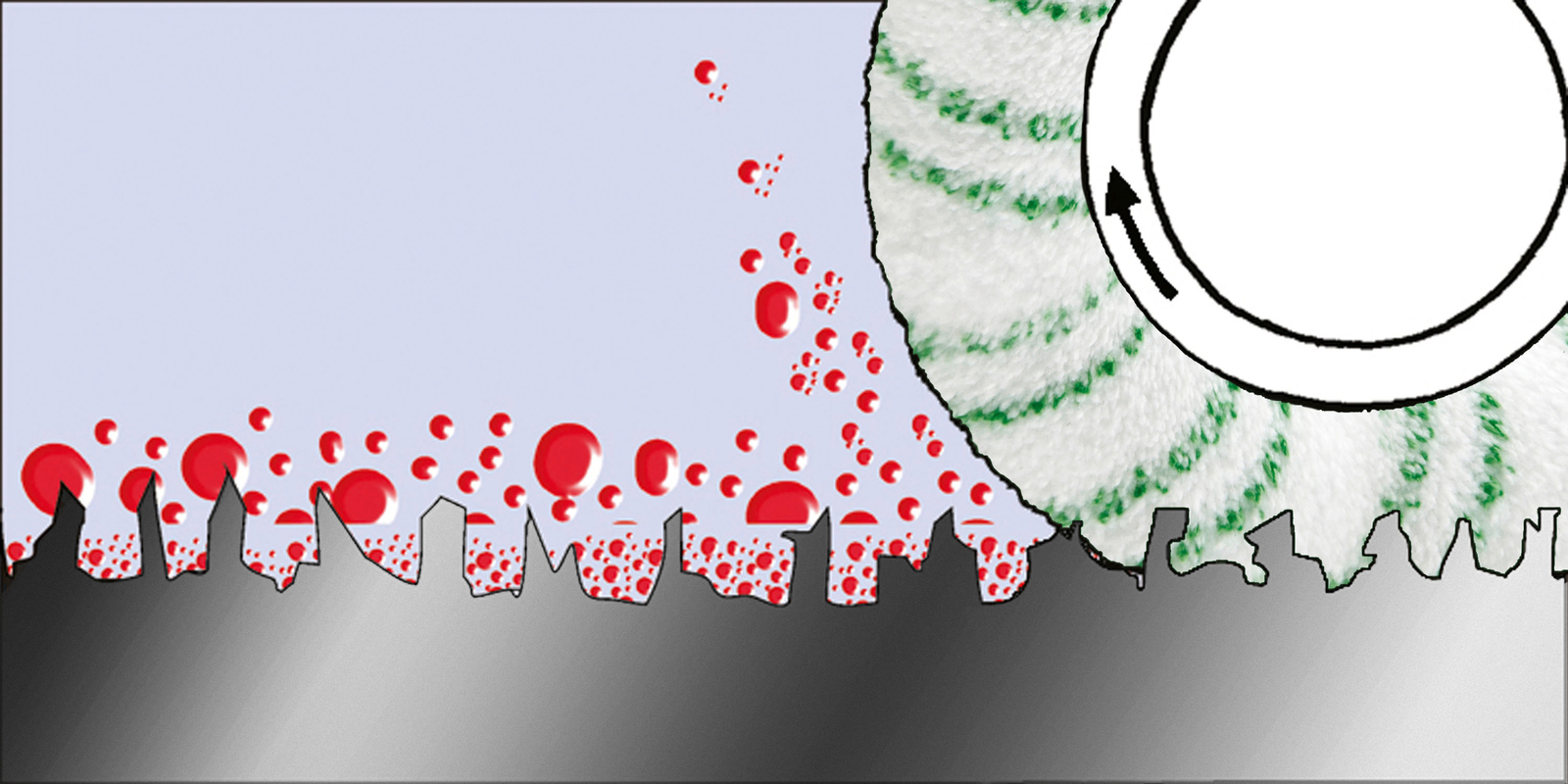

When it comes to machine cleaning, the roller scrubbing head with a microfibre roller pad has proven to be particularly effective because the rollers go hand in hand with pre-sweeping and are self-cleaning. However, it is also possible to clean using disc technology.

It all comes down to the speed

When it comes to achieving the best possible cleaning results on fine stoneware tiles, the microfibre roller speed is crucial (400–1100 rpm depending on the scrubber drier type). This is because the high speed means that the dirt is expelled rather than remaining on the microfibre rollers. As a result, they are self-cleaning and maintain a consistent level of cleaning efficiency. In addition, it is not necessary to undertake the time-consuming process of cleaning the microfibre rollers once the cleaning task is complete. Instead, simply rinsing them under the tap will suffice. Allow the microfibre rollers to dry separately from the machine to prevent an unpleasant odour from being produced.

Fine stone maintenance cleaning

Maintenance cleaning with the roller scrubber machine

For mechanical maintenance cleaning, a surfactant-free fine stoneware cleaner (0.5–3%) is applied evenly using the scrubber drier with a roller scrubbing head and microfibre rollers, worked into the tiles and the loosened dirt is sucked back up again as part of the same process (single-step method). It is not necessary to rinse the rollers with clean water. This cleaning procedure also thoroughly cleans the joints. When performing maintenance cleaning of smaller surfaces and cleaning hard-to-reach areas, it is recommended that you use particularly small and compact scrubber driers. When selecting a cleaning agent for fine stoneware tiles, you must not only look for excellent cleaning power but also whether the cleaning agent is surfactant-free. This will help to loosen dirt and prevent resoiling.

Maintenance cleaning with the large surface wiping machine for small areas and area heavily filled with objects and furniture

If you are cleaning small areas and areas heavily filled with objects and furniture, or very awkwardly shaped areas, it may be more efficient to use a large surface wiping machine with microfibre wiping cloths than a scrubber drier.

Preparation: Remove the loose contaminants (using a vacuum cleaner or microfibre wiping cloths)

Remove stubborn dirt using single-step or two-step wet wiping with microfibre wiping cloths.

- Single-step: Wipe the floor covering in a single step. The loosened contaminants are collected and stubborn dirt may remain on the floor covering.

- Two-step: Firstly, wipe the surface with a large amount of cleaning water with the aim of softening any dirt. The next step is to collect the loosened dirt using a wrung-out microfibre wiping cloth.

Types of dirt and the right cleaning agent:

Dirt on the street:

A neutral cleaner will suffice for removing dirt from the street.

Oily and greasy dirt:

Very oily and greasy dirt can be removed using an alkaline cleaning agent.

Mineral dirt:

Mineral dirt, such as lime, will require an acidic cleaning agent. Joints should be rinsed with water before using the cleaner.

Two-step deep cleaning method

In the case of fine stone floor coverings where a suitably large layer of dirt has formed over the years, there is no other option than to use machine deep cleaning using the roller scrubber machine in a two-step method. Depending on the type and level of dirt, use a good wetting, strongly alkaline or acidic deep cleaner.

The following procedure is recommended:

- If you are using an acidic cleaner, water should be applied to the joints first to soak.

- Apply the cleaning agent (5–20%, depending on the amount and type of dirt) on sections.

- During the contact time, scrub the area using the roller scrubber machine in slightly overlapping strokes and do not let the cleaning water dry, i.e. add to it if necessary.

- Suck up the dirty water.

- Then rinse the floor covering with plenty of clean water in a single-step method.

Alternative: Carrying out deep cleaning using the single-disc machine with microfibre pads or a melamine resin pad

A single-disc machine running at a low rotational speed (for example, 180 rpm) delivers a high torque to the surface and is therefore ideal for the cleaning task. The machine should also be fitted with a cleaning agent tank and pad carrier with microfibre pads/melamine resin pads.

Apply the appropriate cleaning agent (depending on the type of dirt) on sections in strokes. During the contact time (approx. five minutes), scrub the floor covering multiple times in highly overlapping, circular strokes to achieve a uniform cleaning performance.

When applying water and cleaning solution and working the areas to be cleaned, make sure that the cleaning solution does not dry. You should therefore add cleaning solution from the tank, if necessary.

The next step is to suck up the dirty water using a powerful wet and dry vacuum cleaner. Finally, rinse the cleaned area with plenty of clean water and vacuum again with a wet and dry vacuum cleaner.

Tip:

The dirty microfibre pads must be washed in the washing machine before they are used again.

Extra info: Melamine resin pads

For machines with a disc scrubbing head, it is also recommended that you use melamine resin pads. Their excellent mechanism means that, in most cases, you do not even need to use cleaning agents.

In summary: Correct cleaning prevents greying

If fine stoneware tiles – which are difficult to clean due to their microporous structure – are cleaned regularly using the method described, there is no reason to be concerned about greying in the long term. This is where the tile's originality comes into its own. In addition, this also emphasises the anti-slip properties.