Store room cleaning

It is certainly advantageous to have your material store room looking spick and span. Occupational health and safety and the protection of store room material are always key issues. In particular, the floors must be clean and safe to walk on to prevent the risk of accidents caused by inadequate cleaning. Such cleaning can be carried out efficiently using individually configurable (vacuum) sweepers and scrubber driers.

Different cleaning techniques for different types of dirt

When transporting store room material from A to B, any movement made by workers, trolley and food cart will kick up dust. Systematically vacuuming this dust not only helps to ensure cleanliness and safety, but also protects the store room material and prevents it from getting dusty. Moreover, it is not uncommon to find paper scraps from torn labels or transport documents, pieces of foil or wood splinters in store rooms. You can easily remove any dust, fluff and small paper residue with a electric broom, a (vacuum) sweeper or a vacuum cleaner – depending on the size of the store room. When it comes to choosing the appropriate cleaning machines and concepts, the size of the space is a key factor.

Sweeping in the store room: Safely removing dust

Particularly when cleaning store room, a electric broom is preferable cleaner because of the higher volumes of dust involved. During the sweeping process, the electric broom will stirs up the dust with a roller brush, then the dirt will be sweep directly into the waste container which will contain the dust. This means that the amount of dust is reduced during the cleaning process.

In addition to dust and paper residue, you can often find foil residue and packaging tapes or wood splinters from pallets on store room floors. This coarse dirt should be manually removed using a broom or litter picker.

Spot cleaning in the warehouse

For small, occasional cleaning tasks – whether on floors, on shelves or in storage rooms – a wet and dry vacuum cleaner of the appropriate size is the ideal solution since it is versatile and quickly ready for use, particularly in very small storage areas. This makes it quick and convenient to vacuum dust, water marks and spilled liquids. If you are cleaning very small storage shelves, manual equipment consisting of wiping cloths and buckets can also be used.

Floor cleaning in the store room with scrubber driers

The first thing that needs to be considered is the floor type. Store room often use ceramic tiles, such as fine stoneware tiles, because they are robust and have very low moisture absorption. Meanwhile, corporate bigger store room often have industrial flooring made of screed or resilient synthetic coverings such as synthetic resin.

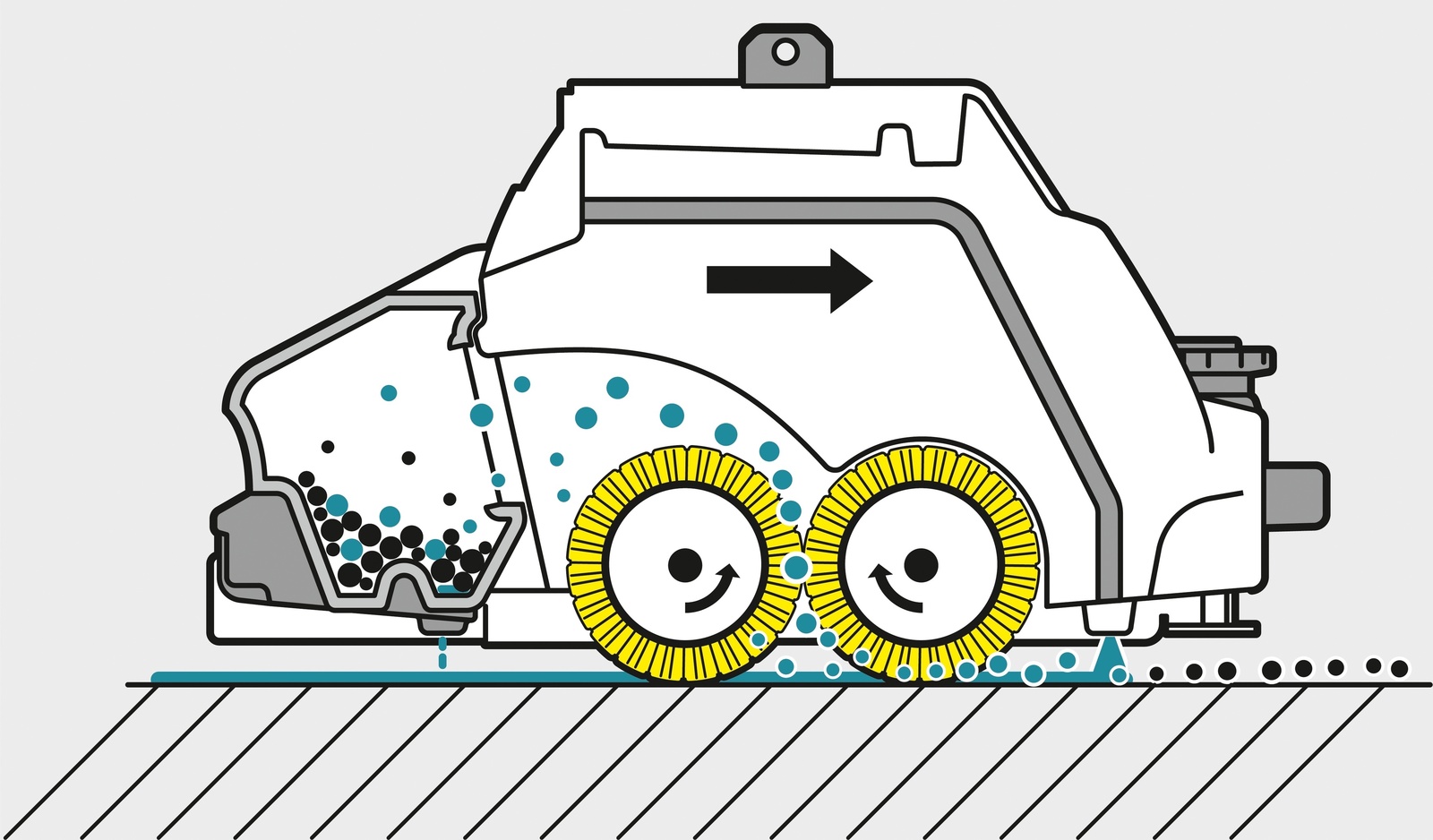

Since store room floors can vary so greatly, there is also a variety of cleaning technologies to choose from. Two of the main criteria for deciding which technology to use are the condition of the floor and the types of dirt in the store room. Scrubber driers with roller technology are particularly well suited to this type of cleaning because of the large amount of coarse dirt. This is because the remaining coarse dirt can be picked up in a single operation thanks to the rollers' pre-sweeping function.

Cleaning fine stoneware tiles

Fine stoneware tiles are an attractive, very popular floor covering which stands out thanks to its robust and slip-resistant qualities, as well as its very low moisture absorption rate. A modern and safe design medium, it is impossible to imagine floor coverings without fine stone nowadays.

Cleaning cement screed

Cement screed is the most commonly used type of screed. This floor covering requires special attention when it comes to cleaning and care. This is because it not only has to withstand a considerable amount of strain, but it also needs to meet occupational safety standards at the same time. For deep, maintenance and intermediate cleaning, it therefore all comes down to selecting the right equipment.

Selecting the right mechanical process (roller or disc) and the appropriate cleaning tool (pad or brush) depends on the floor covering and the type of dirt.

As a general rule, if it does not harm the floor, an alkaline cleaning agent should be used. If you use an acidic cleaning agent, you must ensure that cement joints are pre-soaked in water so as not to damage them.

In particular, when using scrubber driers in store room, you must ensure that these machines leave the floor dry. This is particularly important because the cleaned areas are often immediately walked on again or driven over by forklift trucks. It is imperative that occupational health and safety is ensured.

Tackling a stubborn problem in store room: Removing stain marks

Particularly in store room, heavy item sometimes tend to be drag around from one end of the room to the other every day – leaving stain marks on the floor. It is therefore worth using a cleaning agent specially developed for efficiently removing rubber wear. The agent should be applied undiluted to the dirty areas and then left to work for a few minutes. The scrubber drier should then be used to remove the dirty water. At the end of the cleaning process, you should rinse everything down again with clean water. This wont be applicable for scratches or holes.

Please note: Do not use this method on polymer-based or wax coatings, as the cleaning agent will remove them.