Industrial Vacuuming / Dedusting Solutions

From the mobile machine to the turnkey vacuuming or deduster system

In industry you need a system comprising machines, accessories and services that can be easily integrated in your operations and brings added value. A system in which all products are specially developed to meet the tough industrial requirements. We have the system that makes the difference. The Kärcher industry system.

Chat with Our Experts and Get Your Commercial & Industrial Cleaning Machines and Solutions

- Industry customised solutions tailored to your specific cleaning challenges

- Expert advice and support from our team of experienced professionals

- Environmentally friendly and energy-efficient cleaning technologies

Our quality claim: Made in Germany

A promise you can rely on

High-quality components, comprehensive expertise, a high degree of added value, and professionally trained staff have ensured that our tried-and-tested products offer outstandingly high quality and durability for decades.

We see ourselves as a partner, by your side as you face any industrial vacuuming challenge. Your experiences and feedback are very valuable to us, since our goals align with yours – we aim to develop innovations and products that help you to achieve your goals more quickly and efficiently.

The conditions are tough, our vacuums are ready

Every sector has unique requirements when it comes to the perfect cleaning solution: Process integration, large-scale processing, hazardous substances, narrow time frames, and much more. This requires both universal and specific machines and systems. From metal processing to the automotive industry, from pharmaceuticals to the food industry, Kärcher is the top choices for industrial vacuum cleaners:

- Flexibly mobile or stationary installed industrial vacuum systems

- Ideal for vacuuming large or small quantities

- Complete removal of solids and liquids, as well as large amounts of dust

- Safe vacuuming and disposal of hazardous suction waste

- Machines designed for long-term, industrial use

New name – the same renowned quality. Ringler becomes Kärcher Industrial Vacuuming GmbH

Ringler GmbH is undergoing a comprehensive rebrand for industrial vacuums. In the future, its entire product portfolio will appear under the Kärcher brand name. Our products will be supplied as standard in the new anthracite corporate colour, unless otherwise requested by the customer. With this initiative, Kärcher is reinforcing the uniform appearance of all products offered by the corporate group, as well as its strategic alignment, which keeps you, the customer, in focus.

The advantages for you: From now on, you will benefit even more from a harmonised product portfolio from an established international brand – Kärcher.

Kärcher Industrial Vacuuming GmbH is also by your side as we navigate the COVID-19 pandemic.

The Kärcher Industrial Vacuuming product service at a glance:

- Standard machines are available immediately "off the shelf"

- Individual customer solutions can still be produced quickly thanks to our well-stocked stores

- The time scale of project quotations remains unchanged thanks to fully available sales and project planning

- Spare parts supplies are also guaranteed due to high stock levels

We look forward to hearing from you on +49 (0) 7195 9030.

Monday to Friday from 07:00 to 20:00 and Saturday from 08:00 to 16:00

To protect our customers, suppliers and staff, we have of course adjusted the hygiene and safety measures in place at our premises. In doing so, we have followed specifications from the WHO and the Robert Koch Institute.

With kind regards,

The Kärcher team

Over 50 years of expertise

With the Kärcher industrial vacuum system, you benefit from over 50 years of experience. We are in close touch with our customers worldwide in order to analyse existing and new tasks and optimally adapt our products to these applications.

YOUR INDUSTRY – OUR VACUUMS. KÄRCHER INDUSTRIAL VACUUM SYSTEMS ARE A HIT IN A WIDE RANGE OF SECTORS AND TARGET GROUPS. DAY IN, DAY OUT.

Industrial vacuum cleaners from Kärcher to suit every sector.

YOUR DIRT IS OUR PROBLEM. KÄRCHER HAS THE RIGHT RANGE FOR ANY APPLICATION.

The right solution to any problem

Our Kärcher industrial vacuum cleaners and industrial dust extractors offer you solutions for every industrial vacuuming task: Whether flexible and mobile or stationary, for vacuuming anything from coarse swarf to the smallest suspended particles, for small or large quantities, for liquids or solids, for unproblematic or hazardous material.

Industrial vacuum cleaners

Industrial vacuum cleaners are designed for the stationary or mobile vacuuming of dry and wet swarf, coarse dust and similar suspended particles. Industrial vacuum cleaners work at a high vacuum with a relatively low air flow.

INDUSTRIAL VACUUMS FOR LIQUIDS/SWARF

INDUSTRIAL VACUUMS FOR LARGE QUANTITIES OF ABRASIVE SWARF AND LUBRICANTS

Vacuum cleaners that effortlessly endure several hours daily or continuous operation 24/7 are needed in industry. The spectrum of substances ranges from small to very large quantities of abrasive swarf and coarse particles to discharged media through to liquids such as oil, cooling emulsion and water.

INDUSTRIAL VACUUM CLEANERS FOR SOLIDS/DUSTS

THE VACUUM CLEANERS WITH THE SPECIAL FILTER ENGINEERING

Diverse substances and media have to be vacuumed in the different industries. Discharged media, hazardous dust, fine and coarse swarf, sand, spray agents, all types of fibres, food remnants, organic substances, very light to very heavy materials all place strict requirements on the filter engineering used. In our Kärcher industry vacuum system, you will find the optimal filter for every task, regardless of whether it is daily, at hourly intervals or in continuous operation 24/7.

EX INDUSTRIAL VACUUMS

CERTIFIED SAFETY FOR POTENTIALLY EXPLOSIVE ATMOSPHERES

Vacuuming in potentially explosive atmospheres places the highest demands on machine quality. Kärcher industrial Ex vacuums meet these standards and some are certified by TÜV Süd and IBExU.

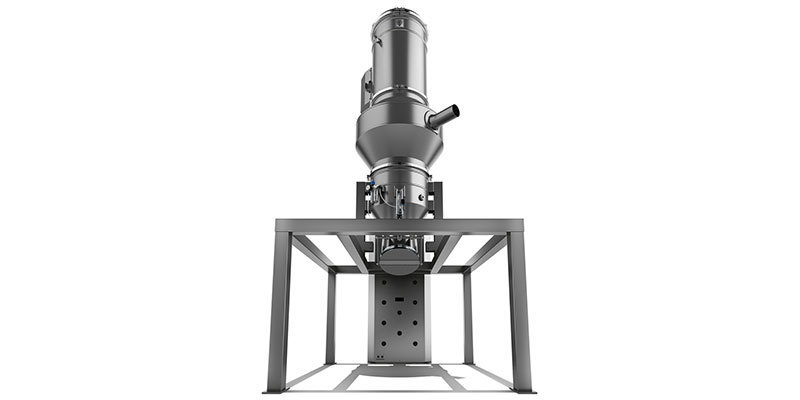

INDUSTRIAL DUST EXTRACTORS

FOR EFFECTIVE COLLECTION OF SUSPENDED PARTICLES

Suspended particles can vary greatly: Fine dust, hazardous dust, fine swarf and all kinds of abrasion. In many industries the continuous vacuuming of process dusts from metals, glass, stone, textile fibres, agricultural products or chemicals directly in the process is essential. Our industrial dust extractors reliably capture suspended particles, even in large quantities, in continuous operation 24/7 directly at connected machining centres or filling plants.

EX INDUSTRIAL DUST EXTRACTORS

FOR EVERYTHING THAT IS SUSPENDED IN AIR AND POTENTIALLY EXPLOSIVE

The continuous suction of suspended, explosive particles directly at the point of origin in the process places extremely high requirements on industrial dust extractors. Our dedusters and Ex dedusters have been proving themselves for many years in continuous stationary use 24/7 in many areas of industry, particularly in metal and wood processing, in the automotive, chemicals and pharmaceuticals industries, food industry, paper manufacture, in the rubber and plastic processing industry, as well as in zone 22.

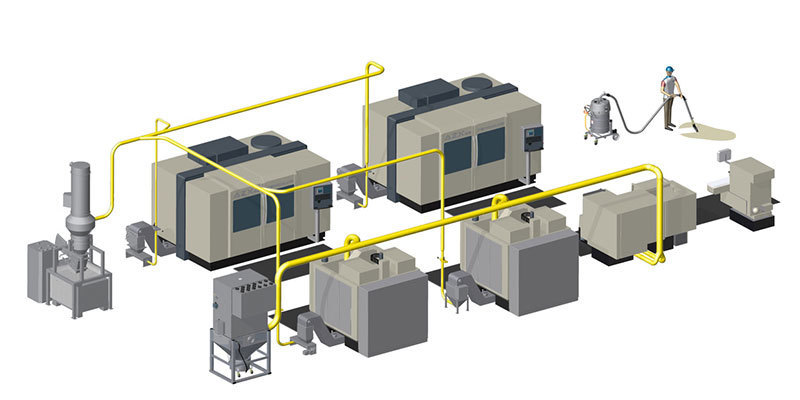

Customer-specific solutions for specific tasks

Individual solutions

The requirements of industrial vacuuming systems can be very specific. We plan every system individually to your specific needs. Our services range from the simple mobile solution through to highly complex, specifically adapted and tightly piped industrial vacuuming solutions. With more than 50 years of experience in the development and realisation of industrial vacuum systems, we are your competent partner. As a result, you get efficient complete solutions from a single source.

Pipelines – perfectly connected performance.

Our stationary industrial vacuums can be used as single- or multi-user systems with hand-held suction points or directly integrated into the process. To enable this, we can provide you with all the necessary components, from the suction points and accessories to individually configured pipelines.

Our DNA

Who we are: The expert in industrial suction solutions.

With over 50 years' experience in the sector, you can rest assured that you're in expert hands with us. Our professional team will work together with you to design the perfect solutions to meet your needs using our extensive product range, as well as providing you with comprehensive expert advice. We are dedicated to helping our customers to create clean, safe working environments using efficient cleaning solutions.

What we offer: High-quality solutions that you can trust.

With our solutions, consisting of high-quality industrial vacuum cleaners with a range of versatile accessories for a range of applications, we make your everyday production significantly easier. Our solutions are complemented by service concepts that ensure your industrial vacuum solution is always ready for use. We are by your side at any time to provide help and advice. That's a promise you can rely on.

What shapes us: Like two sides of the same coin, we represent the decades of experience amassed by Ringler GmbH and its rebrand as Kärcher Industrial Vacuuming GmbH.

High-quality components, comprehensive expertise, a high degree of added value, and expert staff have ensured that our tried-and-tested solutions offer outstandingly high quality and durability for decades. With our combined experience in development, production, sales, services and application engineering, we help you to create a cleaner, safer, more environmentally friendly production facility.

WELDING

Our high degree of added value enables us to react flexibly to your needs.

PAINTING

We are more than happy to provide our industrial vacuum systems to your colour specifications.

INSTALLATION

Made in Germany – optimally structured work processes ensure the highest quality standards.