Floor cleaning: Mechanical cleaning and disinfection with floor scrubbers

For wet cleaning of hard and resilient floor coverings, floor scrubbers are used in addition to manual cleaning equipment. Floor scrubbers can wet scrub in one step and immediately absorb the dirt and debris. This way, cleaning is carried out both hygienically and efficiently.

Disinfection of floors with floor scrubber

Floor scrubbers can be used for the disinfection of floors. It is important to observe both the correct chemical dosage and the exact application time according to the manufacturer's specifications.

Procedure for the mechanical disinfection of floors

For successful disinfection, sufficient active ingredient must reach the floor surface. In order to achieve this, the flow rate should be selected in relation to the floor covering so that an even wetting is given. It is helpful to use microfibre textiles or pad material - brushes are less suitable for this.

In order to maintain the required reaction time, it is essential to work in the one-step method - i.e. without suction. The disinfectant solution is simply applied to the floor with the floor scrubber. Then the surface is allowed to dry.

Special challenge: structured floor coverings

Textured floor coverings are more difficult to clean with manual cleaning systems such as wide wiper racks with mop covers. The problem is that dirt and detergent/care product residues can be wiped off by the structure. On one hand, these residues are unattractive and on the other hand they provide a breeding ground for bacteria.

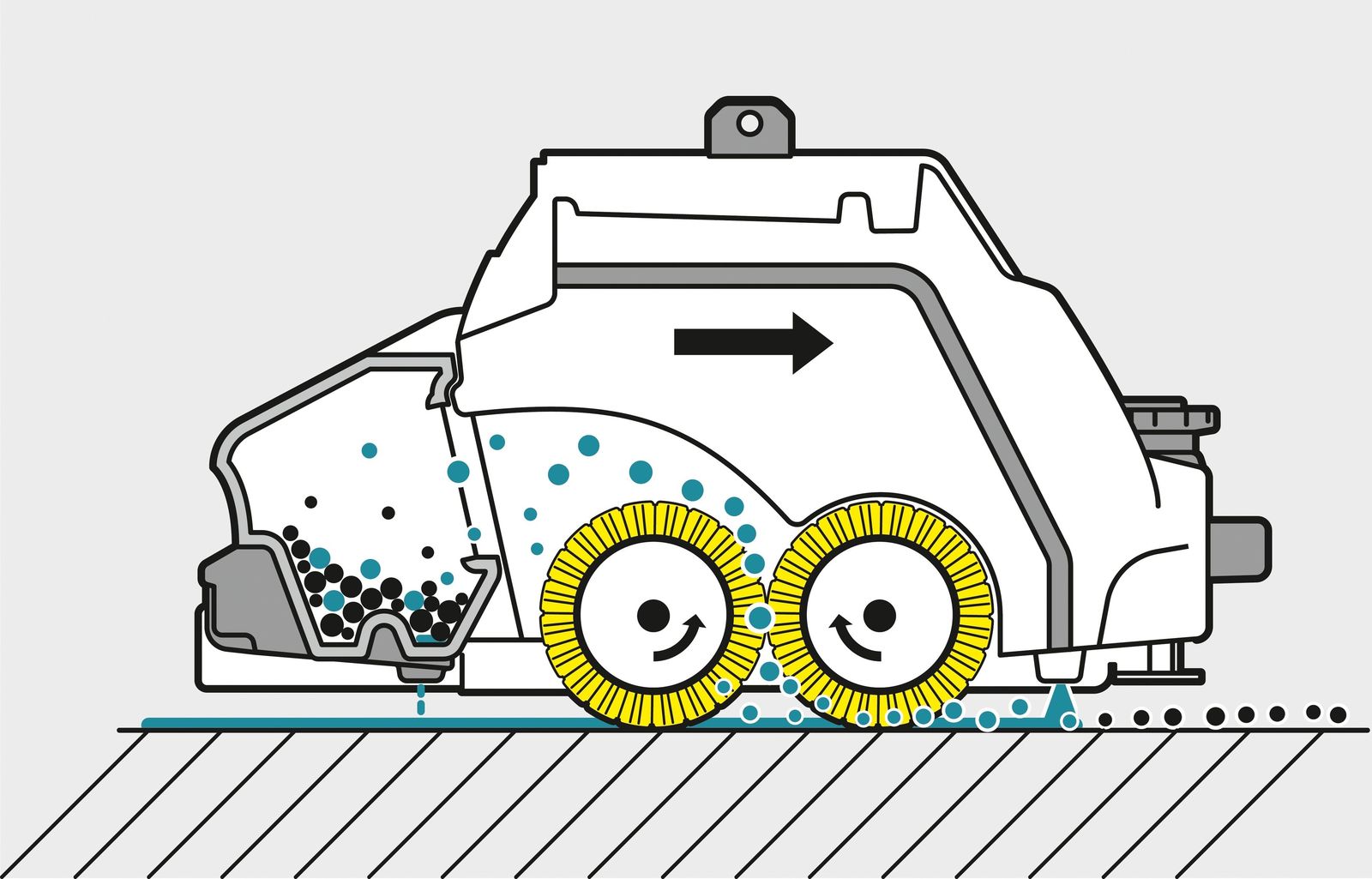

This problem can be avoided by using floor scrubbers with roller brush technology, as these use soft brushes to reach into the structure and loosen the dirt that is then being vacuumed off. Another advantage of roller brushes is that even coarser dirt particles are swept up and the step of pre-sweeping is saved.

Post-processing of floor scrubbers

The floor scrubber must be thoroughly cleaned or disinfected after the disinfection activity is completed. In addition, the excess disinfectant solution must be drained from the fresh water tank to prevent the machine from becoming contaminated.

Ideally, the fresh water cover, fresh water drain cover and the dirty water cover should remain open after dismantling to aid rapid drying.

Cleaning and disinfection according to HACCP (Hazard Analysis Critical Control Point)

In particularly hygiene-sensitive areas such as hospitals or kitchens, the premises and existing equipment must be kept clean by careful cleaning and, if necessary, disinfection. Since different areas and devices have different cleaning intervals, a cleaning plan must be designed and visibly hung up in the respective area that is to be cleaned. This plan has to show in detail:

- what (equipment, surfaces, floors),

- when (after use, daily, weekly),

- with what (detergent and dosage)

- and by whom (responsible employee)

it is to be cleaned.

Completed work must be precisely recorded and documented by signature in a comprehensible way to enable controlling. It should be noted that cleaning and disinfection are two different processes. Cleaning aims to remove contamination, i.e. any undesirable substance including product residue, microorganisms, and detergent and disinfectant residue. Thorough cleaning has been proven to remove over 90% of microorganisms and germs from surfaces.

Disinfection involves chemical and physical processes to kill microorganisms to a level that is neither harmful to health nor impairs the quality of food.