High-pressure cleaner HD 25/15-4 St

The Kärcher HD 25/15-4 St is designed for intensive continuous use. It offers pressure of 150 bar and a flow rate of 2500 l/h and can be used by up to 3 users simultaneously.

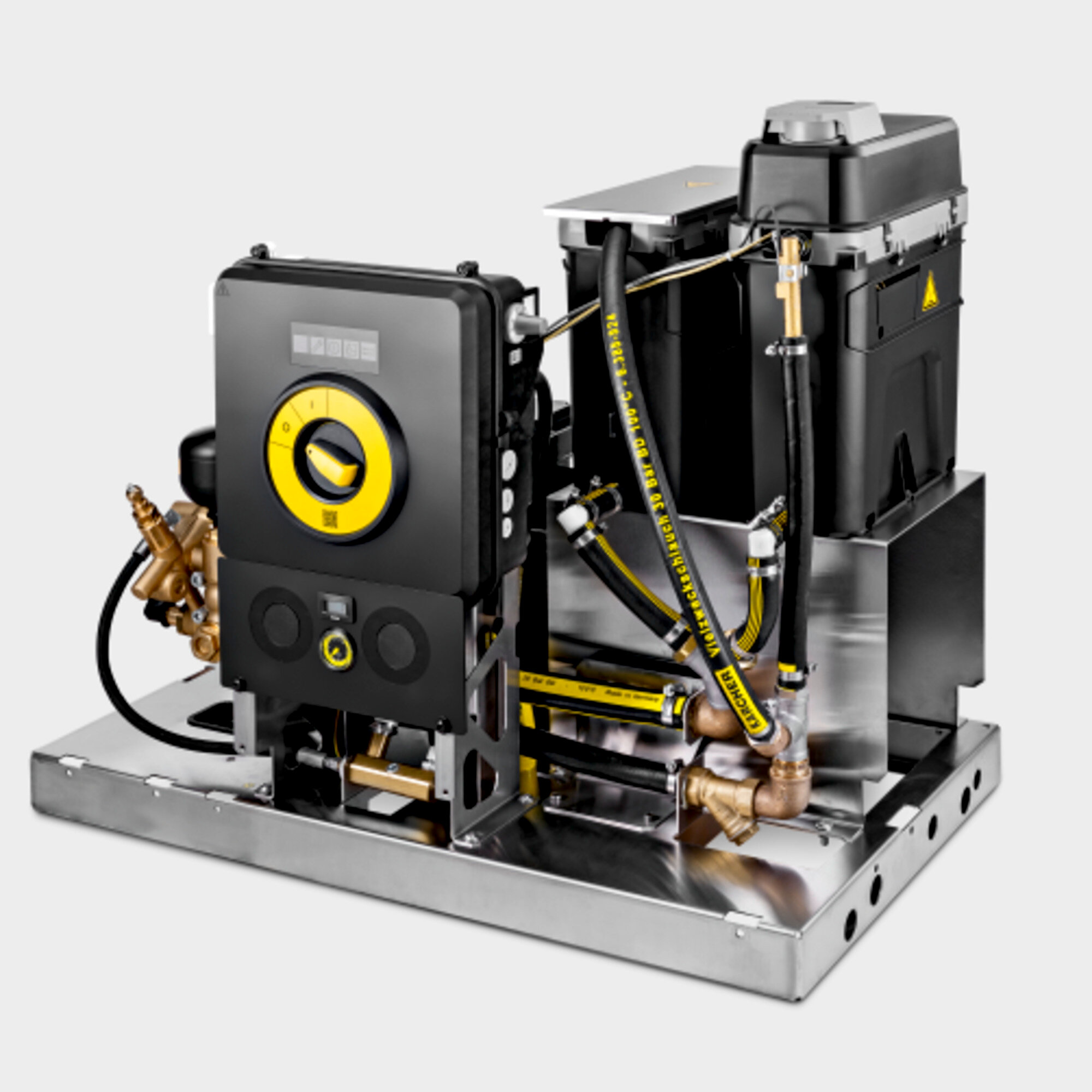

The stationary cold water high-pressure cleaner HD 25/15-4 St is designed for businesses with constant and high cleaning requirements. With a working pressure of 150 bar and a flow rate of 2500 l/h, it offers optimal conditions for continuous use in tough environments. Thanks to the high flow volume, the machine can be used by up to 3 users simultaneously. The robust design with crankshaft pump and brass cylinder head, as well as a stainless steel frame and cover, guarantees a long service life. The durable, slow-running 4-pole electric motor with soft start is designed for continuous use. An integrated display shows operating parameters, error messages and maintenance instructions. Two water supply tanks ensure a constant water supply and dry-running protection for the pump. Calcification protection, pressure gauge and an elapsed time counter are included in the standard version. Easy installation, low maintenance requirements and intuitive operation ensure reliable, efficient use. The HD 25/15-4 St is ideal for industry, food processing, transport, municipalities and agriculture.

Features and benefits

Robust and reliable for tough applications

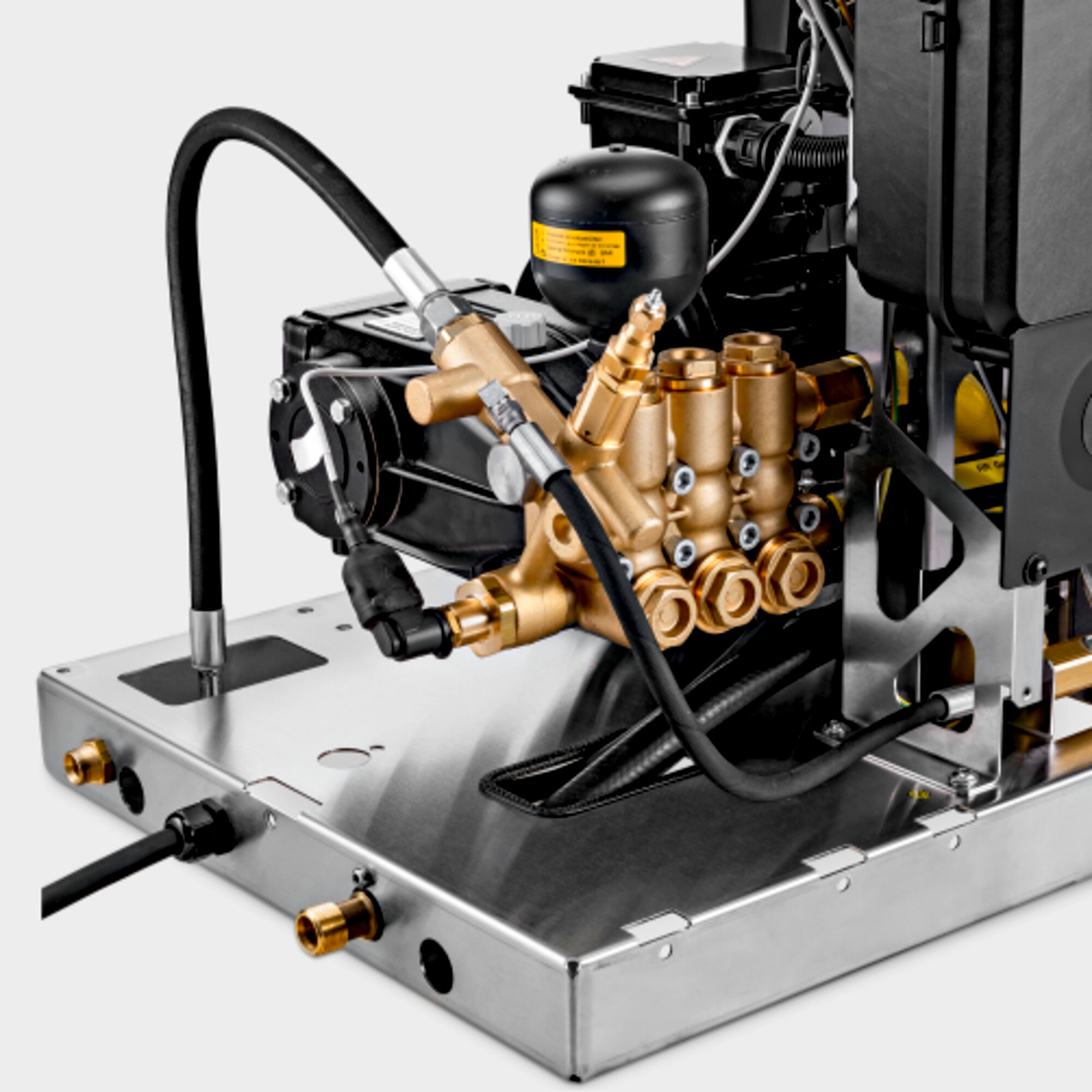

Robust crankshaft pump with brass cylinder head and high-quality materials ensure a long service life. Low-speed industrial pump 4-pole low-speed electric motors with soft-starter guarantee long service life.

Easy and intuitive operation

LED display showing operating status, faults and upcoming pump maintenance. Practical rotary switch for switching on/off. Flexibility in operation, thanks to remote control connection and control of 6 extraction points.

High-quality equipment

Operating time and pressure visible at all times thanks to the integrated elapsed time counter and pressure gauge. Very robust stainless steel frame and cover. Corrosion-resistant, durable and hygienic, ideal for tough environments. Two supply tanks with float valve, dry-running protection, temperature monitoring in the water inlet and descaling protection.Is ready for use quickly at any time

- The pump starts as soon as the trigger gun is activated, allowing convenient working from any supply point.

- Ready at the push of a button, with no set-up times or transporting mobile machines.

- The machine is always ready to go for maximum productivity and flexibility.

Simultaneous use by up to 3 users possible

- No set-up times thanks to immediate cleaning start at the extraction points.

- Increased productivity and time savings through parallel completion of cleaning tasks by several employees.

- Savings in investment and maintenance costs thanks to a centralised, high-performance machine for multiple operations instead of several high-pressure cleaners.

Electronic monitoring for greater operational safety.

- Switches off in case of leaks or phase failure.

- Overvoltage and undervoltage protection.

- Protects the pump against dry running.

Developed for tough applications

- Durability and reliability thanks to stainless steel, brass and robust construction for continuous use, minimum downtime and low maintenance effort.

- Cleaning performance and short set-up times thanks to the fixed installation increase productivity.

- Cost-effectiveness thanks to long service life and low repair costs for long-term economical operation.

Simple maintenance and very easy servicing

- Minimum downtime thanks to easy access to all components.

- Less downtime and longer productivity thanks to faster routine maintenance and repairs.

- Lower operating costs due to reduced repair costs.

Flexible and versatile

- Suitable accessories for every work site and every application can be individually selected from the Kärcher high-pressure range.

- Flexible use, thanks to new extraction points for additional areas and higher cleaning requirements.

- High productivity, thanks to simultaneous use by multiple users at different operation sites.

Extensive range of accessories and attachment kits

- Automatic pressure relief is available as an option.

- Remote controls can be used directly at the point of use.

Specifications

Technical data

| Number of current phases (Ph) | 3 |

| Voltage (V) | 400 |

| Frequency (Hz) | 50 |

| Flow rate (l/h) | 750 - 2500 |

| Working pressure (bar) | 100 - 150 |

| Max. pressure (bar) | 200 |

| Inlet temperature (°C) | 50 |

| Power cable (m) | 5 |

| Water inlet | 3/4″ |

| Number of users | 3 |

| Portability | stationary |

| Weight (with accessories) (kg) | 153,5 |

| Weight incl. packaging (kg) | 164,1 |

| Dimensions (L × W × H) (mm) | 980 x 580 x 815 |

Scope of supply

- Servo Control

- Frame and cover: Stainless steel

- Prepared for Servo Control

Equipment

- Crankshaft pump with ceramic pistons

- Calcification protection

- Dry-running protection

- Large water fine filter

- Storage tank with float valve

- Elapsed time counter

- Prepared for remote operation

- Sight glass for oil level

- Oil dipstick

- Air-cooled motor

Application areas

- Designed for companies and businesses that have constant and high cleaning requirements

- Cleaning of stables, milking parlours, agricultural machinery and vehicles in agriculture

- Suitable for the food processing industry, such as the meat and sausage, dairy, bakery, confectionery and beverage industries

- Ideal for applications in the food, cosmetics and chemicals industries

- Vehicle fleets and transport companies: in wash halls and depots where trucks, buses or other commercial vehicles need to be cleaned regularly

- For cleaning in workshops, garages, building yards, vehicle fleets in municipal facilities

- Perfect for use in vehicle cleaning, in the construction and transport sectors, as well as industry

- Versatile applications in industrial settings, e.g. for cleaning production facilities

- Vehicle and machine cleaning in the automotive, industry and agricultural area

- Suitable for use in production halls, warehouses, logistics buildings and heavy industry facilities